Total System Weight and Power

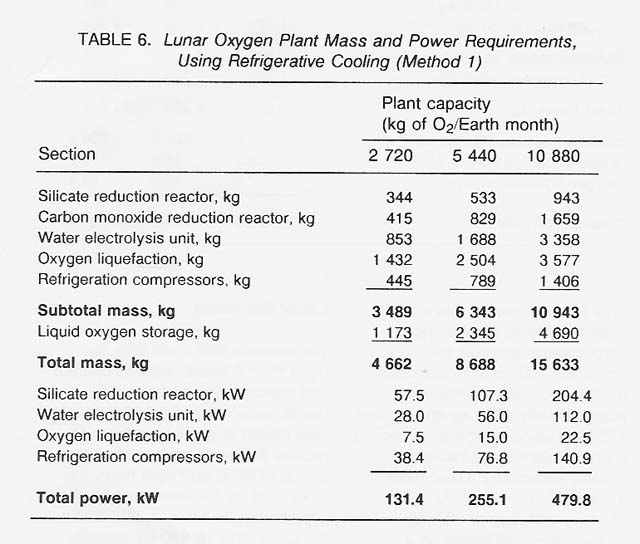

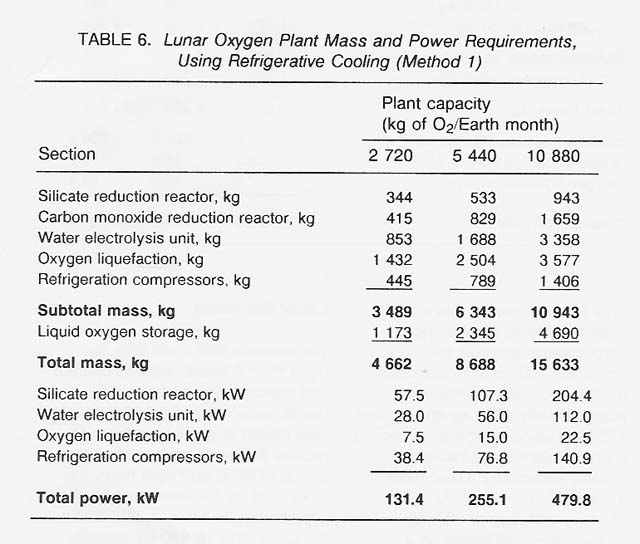

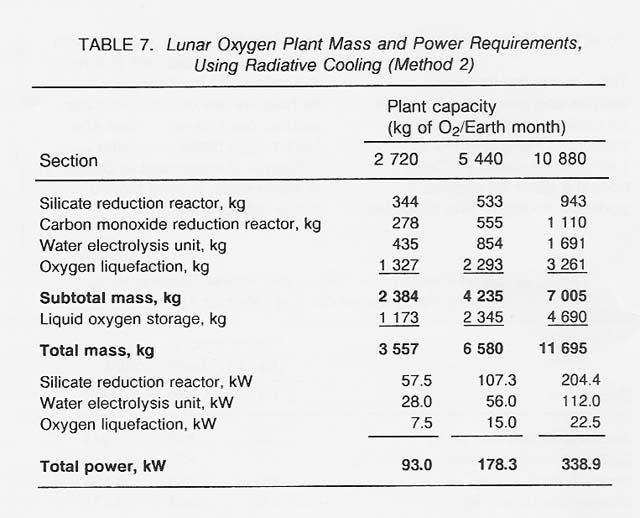

Table 6 lists the total system weights and power requirements for lunar oxygen plants of three capacities, using method 1 (refrigerative cooling). Table 7 does the same for method 2 (radiative cooling). The differences in weight and power requirements for the two methods are striking, indicating that heat rejection techniques are of major importance in lunar plant design. (See Abe Hertzberg's paper in volume 2, "Thermal Management in Space.") In either case, scaling factors remain about constant.

This study indicates that a lunar plant employing the Aerojet carbothermal process to produce 2720 kg' of oxygen per month would have a mass of approximately 4660 kg and require 132 kWe using refrigeration cooling; a similar plant using radiative cooling exclusively would have a mass of approximately 3561 kg and require 93 kWe. All estimates are based on a conservative approach to the problem.

Labor Estimates

We estimate that it will take no more than 8 hours' work to operate and maintain any of the three plants under study for 24 hours. One month of plant operation will require 240 work-hours. Based on a cost of $500 OOO/work-hour, the labor cost for the manufactur'e of 1 kg of oxygen using the 2 720-kg, 5 440-kg, and 10 880-kg capacity plants is $44 000, $22 000, and $11 000, respectively (1989 dollars).

Cost Comparisons

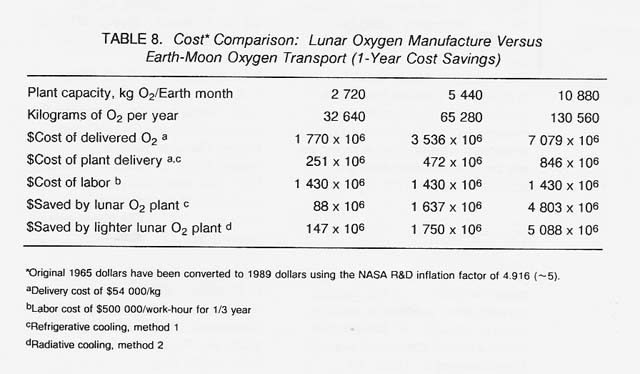

The dollar costs for the manufacture of oxygen on the Moon can be compared with the cost of delivering oxygen from the Earth by using a labor cost of $500 OOO/work-hour and a transport cost of $54 OOO/kg of payload. This cost comparison is given in table 8. The manufacture of 2720 kg of oxygen per month for 1 year would cost $1.71 billion (method 1, most conservative estimate), while the transport of an equivalent amount of oxygen would cost $1.80 billion.

The cost of storing oxygen on the Moon is included in the cost of manufactured oxygen but not in the cost of transported oxygen. Utilizing propellant tanks from lunar landing vehicles to store oxygen on the Moon would reduce the cost of manufactured oxygen but not affect the cost of transported oxygen. If the storage cost were not included, the cost difference would be greater.

The data reported in table 8 dramatically indicate that much greater dollar savings will be realized by the manufacture of propellant oxygen on the Moon as the oxygen requirements are increased above 2720 kg/month.

Conclusion

We have shown with laboratory experimentation that the Aerojet carbothermal process is feasible. Natural silicates can be reduced with carbon or methane (see Rosenberg et al. 1965c for methane results). The important products are carbon monoxide, metal, and slag. The carbon monoxide can be completely reduced to form methane and water. The water can be electrolyzed to produce hydrogen and oxygen. A preliminary engineering study shows that the operation of plants using this process for the manufacture of propellant oxygen has a large economic advantage when the cost of the plant and its operation is compared to the cost of delivering oxygen from Earth.

Bibliography

Marshall Space Flight Center. 1963. Lunar Logistic System, Vol. X, Payloads. Report MTP-M- 63-1, March.

R~senberg, S. D..; G. A. Guter; F. E. Miller; and G. R. Jameson. 1963. Research on Processes for Utilization of Lunar Resources. Aerojet-General Summary Report 2757, Contract NAS 7-225, Dec.; see also Catalytic Reduction of Carbon Monoxide with Hydrogen, NASA CR [ContractQr Report] 57, July 1964.

Rosenberg, S. D.; G. A. Guter; and F. E. Miller. 1964a. Research on Processes for Utilization of Lunar Resources. Aerojet-General Summary Report 2895, Contract NAS 7-225, Aug.

Rosenberg, Sanders D.; Gerald A. Guter; and Michael Rothenberg. 1964b. Requirements for On-Site Manufacture of Propellant Oxygen from Lunar Raw Materials. Presented at 3rd Annual Meeting of the Working Group on Extraterrestrial Resources, Cocoa Beach., FL, Nov. 19.

Rosenberg, Sanders D.; Gerald A. Guter; and Frederick E. Miller. 1965a. Manufacture of Oxygen from Lunar Materials. Ann. N.Y. Acad. Sci. 123:1106-1122.

Rosenberg, S. D.; G. A. Guter; F. E. Miller, and R. L. Beegle, Jr. 1965b. Research on Processes for Utilization of Lunar Resources. Aerojet-General Summary Report 3096, Contract NAS 7-225, Aug.

Rosenberg, S. D.; R. L. Beegle, Jr.; G. A. Guter; F. E. Miller; and M. Rothenberg. 1965c. The Manufacture of Propellants for the Support of Advanced Lunar Bases. Paper 650835 presented at the Society of Automotive Engineers' National Aeronautic and Space Engineering and Manufacturing Meeting, Los Angeles, Oct. 4-8.

Rosenberg, Sanders D. 1985. A Lunar-Based Propulsion System. In Lunar Bases and Space Activities of the 21st Century, ed. W. W. Mendell, 169-176. Houston: Lunar & Planetary Inst.

Rosenberg, S. D., and J. M. Halligan. 1988. The HELIOX Factory: Concepts for Lunar Resource Utilization. Paper LBS- 88-124 presented at 2nd Symp. Lunar Bases & Space Activities of the 21st Century, sponsored by NASA, Lunar & Planetary Inst., AIM, & others, Houston, Apr. 5-7.

|

Curator: Al Globus If you find any errors on this page contact Al Globus. |

|

This site was hosted by the NASA Ames Research Center from 1994-2018 and is now hosted by: