The Space Shuttle Decision:

Chapter 6: Economics and the Shuttle Chapter 6: Economics and the Shuttle

Chapter 6: Economics and the Shuttle

Introduction

The Space Shuttle effort had a full share of optimists, with one of the more noteworthy being Francis Clauser, chairman of the college of engineering at Caltech. As a member of the Townes panel that had reviewed the space program, immediately following Nixon’s election, he had written, “I believe we can place men on Mars before 1980. At the same time we can develop economical space transportation which will permit extensive exploration of the Moon.” His views of the Shuttle were similarly hopeful.

In May 1969, Clauser proposed that the coming decade “will see the cost of space transportation reduced to the point that the average citizen can afford a trip to the Moon.” He emphasized that “when I speak of low-cost space transportation, I define low to be so low that the citizenry can afford to buy tickets for space.” To achieve such a goal, he put his trust in single-stage launch vehicles burning hydrogen for high performance, and capable of routine flight to orbit. With such craft, NASA might undertake as many as 40,000 missions “before flight costs would begin to absorb a major share of its minimal budget.”

Lockheed’s Max Hunter had a similar outlook, as he abandoned his partially-reusable Star Clipper to embrace NASA’s two-stage fully reusable configuration. Speaking at the University of Michigan in mid-1970, he proposed that a schedule of 95 flights per year would bring a cost per flight of some $350,000, or $7 per pound of payload delivered to orbit. He added that Texas Instruments would conduct manufacturing operations in space if the cost went below $50 per pound; at $5 per pound, the Hilton family would build a hotel in orbit. [Astronautics & Aeronautics, May 1969, pp. 32-38; seminar, Department of Aerospace Engineering, University of Michigan, June 15, 1970; Townes, chairman, Report, letter attached. Reprinted in NASA SP-4407, Vol. I, p. 512.]

Was there any basis for such optimism? There was a modest but significant base of experience with existing rocket engines and with the X-15. In addition to this, experience with commercial airliners offered a set of approaches that appeared to be potentially useful. Other approaches reflected the work of design engineers, who expected to meet specifications calling for low cost.

Why People Believed in Low-Cost Space Flight

In October 1969, at a Space Shuttle symposium held in Washington, George Mueller presented opening remarks:

The goal we have set for ourselves is the reduction of the present costs of operating in space from the current figure of $1,000 a pound for a payload delivered in orbit by the Saturn V, down to a level of somewhere between $20 and $50 a pound. By so doing we can open up a whole new era of space exploration. Therefore, the challenge before this symposium and before all of us in the Air Force and NASA in the weeks and months ahead is to be sure that we can implement a system that is capable of doing just that.

Let me outline three areas which, in my view, are critical to the achievement of these objectives. One is the development of an engine that will provide sufficient specific impulse [a measure of performance, equivalent to exhaust velocity], with adequate margin to propel its own weight and the desired payload.

A second technical problem is the development of the reentry heat shield, so that we can reuse that heat shield time after time with minimal refurbishment and testing.

The third general critical development area is a checkout and control system which provides autonomous operation by the crew without major support from the ground and which will allow low cost of maintenance and repair. Of the three, the latter may be a greater challenge than the first two. [Proceedings, NASA Space Shuttle Symposium, October 16-17, 1969, pp. 3-8.]

At that time, when the 50,000-pound payload was still the standard, Mueller’s cost goal represented a cost per flight of from $1 million to $2.5 million. This would not allow ordinary citizens to buy tickets into space, and was somewhat higher than Max Hunter’s figure of $350,000. Regardless, if realized, it would be a long leap downward from the $185 million of a Saturn V.

The X-15 had already established itself as a reusable and piloted rocket airplane, with performance approaching at least that of a shuttle booster, though not of an orbiter. As program participants developed experience, they brought the turnaround time to as little as six working days. Individual X-15 aircraft could fly as often as three times a month.

A careful post-flight inspection followed each mission and took about two days. Inspectors examined the aircraft closely, looking for loose fasteners, cracks, hydraulic or propellant leaks, and overheating. Technicians checked the engine system for leaks using pressurized helium. The pilot reported in-flight problems, while other problems became known through study of data from onboard instruments. These post-flight activities guided subsequent work of maintenance and repair.

The engine received particularly close attention. At the start of the X-15 program, an engine run was required before each flight. In subsequent years, an engine still required a pre-flight run after replacement or major maintenance, or after three flights. A test pilot played an essential role during these engine tests, sitting in the cockpit and operating the aircraft systems. These tests disclosed such problems as rough engine operation and faulty operation of a turbine or pump, with the source of the problem being found and fixed.

All aircraft systems received complete tests prior to the next flight. They also received close inspection and overhaul at stated intervals. After every five flights, the landing gear, which was under high stress, was x-rayed for cracks. Because flaps were essential for a safe landing, their gear boxes were checked for wear after every five flights as well. Stability augmentation systems, which helped to maintain control during reentry, were tested for alignment. An engine demanded major maintenance after 30 minutes of operation; it thus had a long life between overhauls, for at full thrust an X-15 would burn a complete load of propellant in less than 90 seconds.

In the X-15 program, the principal maintenance problems centered on structural repairs and on propellant and pneumatic leaks. The latter often resulted from failures of gaskets or O-rings. Most of the structural repair items were minor. Significantly, the hot structure of the X-15, which absorbed the heat of reentry, did not represent an important source of problems. Working at Edwards Air Force Base, a ground crew of modest size successfully handled most issues of maintenance and repair. Three X-15 aircraft thus conducted 198 powered flights between 1959 and 1968, when the program ended. [NASA TM X-52876, Vol. V, pp. 33-44; Miller, X-Planes, pp. 106-111.]

The X-15 represented one element of experience pertinent to the Space Shuttle. Another element involved the high-performance liquid rocket engines of the 1960s. The Space Shuttle Main Engine (SSME) was initially planned for 100 starts and a 10-hour life, representing a twentyfold improvement over the engine of the X-15. This long life would be essential for a low-cost shuttle, by reducing the number of costly engine overhauls and eliminating downtime due to engine changeouts and major maintenance. Although the engines of the 1960s had not been designed for long life in service, tests had shown that they already were close to achieving the requirement for an SSME.

The RL-10, with 15,000 pounds of thrust, had been the first to show this. As early as 1963, individual engines had been operated for over two and a half hours, with more than 50 restarts. By 1969, the total duration for a single test engine exceeded that of 50 shuttle missions, while a thrust chamber, sans turbopumps, received a series of test firings that totaled more than 11 hours. [Aviation Week, August 31, 1970, p. 38; Astronautics & Aeronautics, January 1964, p. 44; proceedings, NASA Space Shuttle Symposium, October 16-17, 1969, p. 360.]

The engines of Apollo showed similar life. The F-1 was rated for 20 starts and 2250 seconds in total duration. Yet by replacing the liquid-oxygen pump impeller and the turbine manifold at 3500 seconds, test engines achieved as many as 60 starts and total durations of 5000 to 6000 seconds. The J-2 did even better, with a test engine running for 103 starts and 6.5 hours, without overhaul.

“We never wore out an engine of the J-2 type,” recalls Rocketdyne’s Paul Castenholz, who managed its development. “We could run it repeatedly; there was no erosion of the chamber, no damage to the turbine blades. If you looked at a J-2 after a hot firing, you would not see any difference from before that firing. The injectors always looked new; there was no erosion or corrosion on the injectors. We had extensive numbers of tests on individual engines,” which demonstrated their reliability. [Proceedings, NASA Space Shuttle Symposium, October 16-17, 1969, p. 401; AIAA Paper 89-2387; author interview, Paul Castenholz, Ventura, Calif., March 18, 1997.]

This experience meant that existing engine-design practice gave a reserve of engine life that engineers could draw on in meeting SSME goals. SSME requirements, however, were far more demanding because it was to operate at much higher pressures. The chamber pressures of the F-1 and J-2 were modest by later standards: 763 and 982 psi, respectively. At full power, that of the SSME would be 3280 psi. Preburners, which fed the main combustion chamber, were to operate at pressures up to 5500 psi. In turn, these preburners received propellants from the turbopumps, whose pump discharge pressures had to be higher still: as much as 8000 psi.

The turbopumps thus would face enormous stresses, produced not only by pressure but by extremes of temperature. These turbopumps would be driven by hot gases and were to pump liquid oxygen and liquid hydrogen at temperatures hundreds of degrees below zero. They had to be built as compact units – which meant that across a distance of no more than two or three feet, a red-hot turbine would be driving a deeply chilled pump. These temperatures would cause the metals and materials of a turbopump to expand and contract every time the engine was fired, and designers had to ensure that the resulting stresses would not produce cracks.

In addition, the turbopumps were to operate at extraordinary power levels. The hydrogen turbopump, more powerful than the oxygen pump, was to approach 75,000 horsepower—in a unit the size of an outboard motor. This compared with the 55,000 horsepower that drove the liner Titanic early in the century, in an era when engine rooms covered an acre of space below decks. Moreover, its rotating turbomachinery was to spin at over 36,000 rpm. Yet while its bearings had to work without lubrication, for the use of oils or greases was out of the question. At the hot end of a shaft, these lubricants would evaporate. At the cold end, they would freeze solid. Within the oxygen turbopump, exposed to liquid oxygen, such substances would explode. [Rocketdyne, Expendable Launch Vehicle Engines; Pocket Data RI/RD87-142 (Rocketdyne), pp. 1-9, 2-15, 2-17, 2-29, 2-31; Lord, Night, p. 103.]

Pratt & Whitney built prototypes of such pumps for both its XLR-129 and its NASA 350,000-pound engine, and Rocketdyne expected to do likewise. To deal with thermal stresses produced by the temperature extremes, designers were accustomed to using high-strength ceramics that expanded and contracted less than metals. Though hydrogen made some alloys brittle, designers could protect them with thin coatings of gold, deposited on hot engine parts. Though this led to talk of “gold-plated engines,” gold was desirable because it would not corrode.

There were a variety of means to design turbopumps. Conventional ball bearings were of stainless steel, but specialized ceramics and glasses offered greater hardness and resistance to wear. It even was possible to dispense with ball bearings altogether and introduce hydrostatic bearings that relied on fluid pressure to maintain a clearance between a shaft and its housing. This avoided having parts in contact that could experience friction and wear. While hydrostatic bearings demanded a great deal of testing to ensure that they would operate properly, Rocketdyne’s Robert Biggs noted that when such bearings were used on the SSME, they “worked beautifully.”

Although a complete SSME would have 45,000 parts, it was not necessary that all of them last for the rated engine life between overhauls. Engineers expected to design for ease of maintenance, by providing for ready replacement of some parts and components. “Line-replaceable units” could be removed and reinstalled while leaving an engine as a whole attached to its mounts. Through these approaches — design for maintainability, design for relief of thermal stresses, alternate means for building heavily stressed bearings, reliance on the reserve of engine life afforded through existing experience — engineers expected to meet the challenge of developing an SSME with long life. [Author interviews: Robert Biggs, Canoga Park, California, January 21, 1997; Paul Castenholz, Ventura, California, March 18, 1997.]

Other alternatives existed in the area of thermal protection for the booster and orbiter, to guard against the heat of reentry. Hot structures offered a well-established but complex and tricky approach; while tiles of matted silica fiber promised simplicity, they were in an early stage of development in 1970. There also was a third approach: ablative heat shields of light weight and low cost.

In their earliest forms, such heat shields dated to the missile nose cones of the mid-1950s. They had been standard elements of the Mercury, Gemini, and Apollo spacecraft, showing particular merit on the latter, which returned from the moon by re-entering the atmosphere with twice the energy of a return from earth orbit. Ablative shields carried away the heat of reentry by vaporizing or charring in a controlled manner; hence they were not reusable. New versions, however, had densities as low as 15 pounds per square foot, matching the low weight of tiles. There also was strong interest in low-cost methods for fabrication of large ablative panels that could be installed readily and removed while covering substantial areas of a shuttle’s wings and body. Engineers thus were confident that they could use such panels as an interim method for thermal protection, allowing them to get a shuttle up and flying even if development of the tiles were to encounter delays.

In addition to this, while the tiles were to cover large areas, they could not cope with the reentry temperatures of a shuttle’s nose and wing leading edges, which would range from 2500 to 3500 °F. For these limited regions, still another alternative was under development: carbon composites. Carbon had an excellent ability to withstand high temperatures; vanes of graphite, dipping into the rocket exhaust of the V-2, had steered that missile as far back as 1942. Being brittle, graphite was unsuitable for use in thermal protection. The new carbon composites, however, were resilient, and reusable.

These composites drew on a recent invention: carbon fiber, while fragile, possesses some strength.” Such fibers could be woven into cloth, with the cloth being impregnated with a specialized resin. A contractor would pile layers of this resinous cloth within a mold, forming a layup. Heated to high temperatures in the absence of oxygen, the resin would pyrolize, emitting gases and turning into carbon as well. The resulting article, treated with a coating to resist oxidation, showed promise at temperatures up to 4000 degrees. [Proceedings, NASA Space Shuttle Symposium, October 16-19, 1969, pp. 581-591; NASA TM X-52876, Vol. III, pp. 185-200; AIAA Paper 73-31, pp. 14-15, 35-36; Jenkins, Space Shuttle, pp. 129-131.]

A strong technical background was also emerging in the third of Mueller’s critical areas, which he had described as “a checkout and control system which provides autonomous operation by the crew and which will allow low cost of maintenance and repair.” Mueller had outlined a basis for such a system in a May 1969 briefing to shuttle contractors. He had called for an array of sensors and onboard computers that could diagnose the health of a shuttle’s engines and other subsystems, returning such messages as “I am well” or “I am going to be sick.” [See Chapter 3 for a more complete description.]

Computerized checkout offered an important path toward low-cost space flight. Cost meant people, and it was taking a ground crew of 20,000 NASA and contractor employees to prepare and launch a Saturn V with its Apollo moonship. If computers were to eliminate some of these jobs, here was a good reason for this to happen. Computerized checkout also promised more effective maintenance, a topic on which people in the airline industry had a number of pointed comments. [Mueller, Briefing, 5 May 1969; Heppenheimer, Countdown, p. 254.]

In 1968, with computerized checkout still off in the distance, two maintenance managers at American Airlines noted “the difficulty of quickly and accurately locating a fault in our complex airplanes. As a consequence, much of our current troubleshooting efforts are ineffective.” Many aircraft components received an allotted time in service prior to removal for test or overhaul; yet over 80 percent of these “time-controlled” units did not run to their approved time limits. Regardless, it was not desirable to reduce the time between overhauls. Experience had shown that when items were removed for test or for major maintenance, they tended to fail more frequently after being reinstalled.

Troubleshooting, also, was hit-and-miss. We all have had the experience of taking a car to a garage for repair, having a mechanic replace a part, paying the bill — and finding that the problem remains unsolved. Such experiences were also common in the airline industry. The American Airlines managers wrote that

over a recent six-month period, 44 percent of the components replaced during maintenance of the air conditioning system did not eliminate the pilot’s complaint. Fifty-two percent of the replacements in the autopilot system did not eliminate the pilot’s complaint.

The nation’s airlines thus had a particularly strong interest in computerized checkout. While NASA was quite prepared to develop its own system for the shuttle, the airlines and their contractors could offer valuable experience, while subjecting such systems to the demands of daily use in large fleets over long periods. Pan American World Airways was emerging as an industry leader in this area; in 1970, it was providing onboard fault detection and analysis for cockpit instruments and items of flight equipment. These included the radio altimeter, radio receivers used for navigation and low-visibility landings, transponders that returned a radar signal to make a plane show up brightly on a radar screen, and electrical generating systems.

Pan Am was also extending the use of such airborne monitoring systems to detect faults in engines. Sensors took data on engines during flight; an onboard computer used this data to determine solutions to equations that calculated engine performance. It also compared the solutions to stored values to establish trends in performance. If a trend was unfavorable — if an engine was beginning to deteriorate — a printer on the flight deck would prepare a message and warn the crew. In 1970, a prototype had already been flight-tested aboard a Boeing 707 and was slated for similar testing on a Boeing 747.

During that same year, those airlines became part of the teams that conducted the principal space shuttle design studies. North American Rockwell worked with American Airlines, leading a team that also included General Dynamics, Honeywell, and IBM. McDonnell Douglas linked up with Pan Am, while also bringing in TRW and Martin Marietta. Hence, in seeking airline-style operations for a shuttle, these teams had the counsel and experience of the airlines themselves. [Astronautics & Aeronautics, July 1968, pp. 42-51; NASA TM X-52876, Vol. V, pp. 1-32; National Journal, April 24, 1971, p. 875.]

Of course, NASA was going to have to spend money to achieve low-cost space flight, and development of the Shuttle would not be cheap. This was worrisome, for in pushing the frontiers of technology during the 1960s, the agency had often encountered cost overruns. An in-house review, which Paine received in April 1969, showed that NASA’s principal automated spacecraft programs had increased in price by more than threefold, on average, since their initiation. The costly programs in piloted flight had performed similarly. Gemini had gone from an initial estimate of $529 million, late in 1961, to a final expenditure of $1.283 billion. Apollo, with a program cost estimated at $12.0 billion in mid-1963, ballooned to $21.35 billion by the time of the first moon landing in July 1969. That program indeed had fulfilled President Kennedy’s promise by reaching the moon during the decade of the 1960s, but only because it had drowned its problems in money. [NASA SP-4102, p. 155; NASA SP-4012, Vol. III, p. 61.]

What had caused these overruns? Here too, cost meant people. Major overruns resulted when large technical staffs drew salaries to little effect, as when projects encountered technical stumbling blocks, forcing major redesigns. Such difficulties brought delays and pushed up costs by wasting much of the earlier work. Other delays stemmed from unanticipated failures, such as the Apollo fire in early 1967; this alone accounted for much of Apollo’s overrun. The Shuttle was all too likely to encounter such issues, for it offered technical challenges aplenty. Budget officials therefore were well aware that the cost estimates of the day represented estimates made at the start of a program and were subject to potentially large increases several years down the road. Even so, low-cost space flight indeed appeared feasible.

In summary, people believed in this feasibility because leaders such as Mueller had identified the most promising routes to low cost: engines with high performance and long life, reusable heat shields, and onboard checkout. Experience in engine development, supplemented by a wealth of design alternatives for critical technical problems, promised assurance of a good SSME. Similar alternatives existed for thermal protection, again promising multiple routes to low cost. Major airlines, working in partnership with shuttle contractors, were already taking the lead in developing onboard checkout.

Nevertheless, a question remained: Even if NASA could build its Shuttle, was it in the national interest for the agency to do this?

The Shuttle Faces Questions

In carrying through the increasingly detailed studies that were to precede a major program commitment, NASA had adopted a phased approach, which Paine described in a letter to Congressman Teague:

The first phase (Phase A) consists primarily of an in-house analysis and preliminary study effort to determine whether the proposed technical approach is feasible. Phase B consists of detailed studies and definition, comparative analyses, and preliminary design directed toward facilitating the choice of a single approach from among the alternate approaches selected through the first phase. Phase C involves detailed systems design with mockups and test articles to assure the hardware is within the state-of-the-art and that the technical milestone schedules and resource estimates for the next phase are realistic. The final phase (Phase D) covers final hardware design development and project operations. [Letter, Paine to Teague, May 28, 1970.]

Like the progression of a personal friendship through dating, engagement and onward to marriage, this phased sequence carried increasing levels of commitment at each step. The most noticeable sign of this commitment was the budget. The Shuttle studies of 1969 had held the level of Phase A; they had initially been funded at $300,000 for each of four contractors. The studies of 1970 would constitute Phase B, and were considerably more costly. The SSME alone would receive three such studies, at Rocketdyne, Aerojet General, and Pratt & Whitney, funded at $6 million each. The Shuttle itself, as a two-stage fully-reusable design, would be the subject of two Phase B investigations, conducted by teams led by North American Rockwell and by McDonnell Douglas. Their funding was initially set at $8 million each, and subsequently raised to $10.8 million. [“NASA Space Shuttle Studies” (summary of contracts), April 16, 1971.]

This increasing commitment was sure to bring increasing scrutiny from the Budget Bureau, whose analysts were prepared to seek justification of the Shuttle by applying a standard economic approach. This approach relied on constant or uninflated dollars, thus making it possible to ignore the effects of inflation. Its point of departure lay in the indisputable fact that, during the 1970s, the Shuttle program would require substantial outlays of funds to pay for its development. In exchange for this, the program could hope to reap valuable savings by lowering the cost of space flight, during the 1980s. One then could ask if would not be better and more cost-effective to use the Titan III family instead. As an alternative to the Shuttle, the Titan III was already in hand, and could readily receive technical improvements that would allow it to carry heavier payloads.

On a straight dollar-for-dollar basis, the answer to this question clearly was “no.” The Titan III was an expendable launch vehicle, thrown away after each flight. Hence, even a modest level of space activity would give advantage to the Shuttle, for the continuing costs of Titan III production would quickly exceed the one-time-only cost of shuttle development. With the Shuttle being reusable, its cost per flight, once operational, would be minimal by comparison.

The BoB, however, was not about to assess the merits of the Shuttle in this straightforward way. Instead, it insisted on the use of discounted dollars, reflecting the time value of money. To economists, this concept reflected accepted professional practice and was not a subject for argument. It stemmed from a simple principle: the dollar of next year is worth less than the dollar one holds today, even without inflation.

We apply this principle in our own personal investments, when we purchase a certificate of deposit (CD). This CD ties up money for years, and we will not buy the CD if it will merely keep that money safe for that duration, returning it with no interest earned. Similarly, we will not buy it if it only returns interest at a ridiculously low rate such as two percent per year. We insist on a reasonable rate such as six percent, or four percent after allowance for inflation. That four percent represents the true rate of return, in constant dollars.

On this basis, again in constant dollars, a ten-year CD with value at maturity of $1000 will cost $675 in money we hold today. This is as much as to say that the sum of $1000, payable in 10 years, has a value at present of $675. This also illustrates that not only is tomorrow’s constant dollar worth less than today’s, but that money markets act to determine how much less, and to set the price of securities accordingly.

In working with discounted dollars, the BoB applied a discount rate, analogous to the interest rate on that CD. The Bureau was prepared to set this rate by invoking a concept analogous to investment risk. In securities trading, it is commonplace to demand higher return on investments that carry greater risk. Thus the corporate bonds of AT&T, which are very safe and highly rated, may return no more than six percent, while bonds of riskier companies may pay over eight percent.

For the BoB, the analogous concept was national priority. Many federal programs could be viewed as investments, laying out money in the short-term in hope of realizing a social or economic return in the future. Programs holding high priority — interstate highways, construction of schools and colleges — could receive a low discount rate, analogous to the low interest rate of bonds rated AAA. By contrast, programs of low priority resembled speculative investments, and demanded a high discount rate. The Bureau gave the space program a particularly low priority, and imposed discount rates as high as 10 percent. This was as much as to say that the Space Shuttle, viewed as an investment, was no better than an issue of junk bonds.

The BoB’s analysts were prepared to compare the Shuttle and Titan III in a variety of ways. The comparison would depend closely on the assumed level of activity, the number of flights per year. For a given level, these analysts could determine the discount rate at which the cost of the Shuttle, in discounted dollars, would be low enough to save money. For a given discount rate, such as 10 percent, the BoB could also show whether the Shuttle indeed would be the less costly way to proceed — or whether the Titan III would hold the advantage.

Such analyses, using discounted dollars, in no way amounted to a simple comparison of shuttle development cost to Titan III production cost. If the Shuttle would ever pay for itself, it would do so when operational during the 1980s, using the discounted dollars of the 1980s. Because the discount rate was high, those dollars would have little present value at the immediate moment, in 1970. Hence, the Shuttle would have to promise a discounted cash flow that would be enormous indeed. Its discounted cash savings, achievable during the 1980s and hence worth very little in 1970, would nevertheless have to exceed the cost of development, which NASA would incur during the 1970s.

Hence, in dealing with the BoB, NASA was in the position of a corporation whose officials hoped to finance a major development program by issuing bonds. With the program being speculative, the bonds would feature high risk and would carry high interest. Investors then readily might fear that the company would go broke paying interest before it could realize the return from a successful program. To guard against this, company executives would have to give those investors excellent reasons to believe that the benefits from this return, far off in the future, would be large enough to be worth the wait.

If NASA had held high priority, qualifying for a low BoB discount rate, it would have been in the position of a solidly-managed corporation with a gilt-edged credit rating. Such a corporation, paying low interest on its bonds, might readily carry its indebtedness while awaiting the benefits of its new projects. This interest rate would correspond precisely to the BoB’s discount rate, for with those benefits being discounted less heavily, they would have greater present value and would more convincingly justify the short-term project expense. [AIAA Paper 71-806; Standard & Poor’s Bond Guide (any month), p. 3; letter, Mayo to Paine, Jan. 20, 1970.]

Thus, in August 1969, the BoB had carried through a comparison of the Shuttle and Titan III using discounted dollars. This analysis presented low, medium, and high scenarios for NASA activity, respectively at 15, 20, and 25 flights per year. It also presented low, medium, and high scenarios for Air Force and Defense Department activity, at 15, 20, and 30 flights per year. The 15-per-year rate was close to the current DoD level; the high rate was twice this level.

Shuttle vs. Titan III: Outlays, 1970-1985 (billions of dollars)

| Requirements | Gross Outlays | Cash Outlays Discounted to 1970 Present Value | Shuttle Discount Rate | ||

| 5% rate | 10% rate | (Rate of Return) | |||

| 1. NASA High, DoD High (Averages 55 flights per year) | Shuttle | $9.0 | $6.8 | $5.2 | 9% |

| Titan III | 15.0 | 8.0 | 5.0 | ||

| Benefits | 6.0 | 1.2 | -0.2 | ||

| 2. NASA High, DoD Medium (Averages 45 flights per year) | Shuttle | 7.9 | 5.9 | 4.5 | 8% |

| Titan III | 13.0 | 7.1 | 4.1 | ||

| Benefits | 5.0 | 1.2 | -0.4 | ||

| 3. NASA Medium, DoD Medium (Averages 40 flights per year) | Shuttle | 8.6 | 6.5 | 5.2 | 5% |

| Titan III | 10.6 | 6.5 | 4.1 | ||

| Benefits | 2.0 | 0.0 | -0.9 | ||

| 4. NASA Medium, DoD Low (Averages 36 flights per year) | Shuttle | 8.0 | 6.1 | 4.8 | 4% |

| Titan III | 9.5 | 5.8 | 3.7 | ||

| Benefits | 1.5 | -0.3 | -1.1 | ||

| 5. NASA Low, DoD Low (Averages 28 flights per year) | Shuttle | 7.2 | 5.6 | 4.4 | 1.5% |

| Titan III | 7.7 | 4.8 | 3.1 | ||

| Benefits | 0.5 | -0.8 | -1.3 | ||

Source: Budget Bureau, “NASA Issues Paper,” August 1969: attachment, “Space Transportation System,” August 22, 1969.

The analysis showed that at the lowest level of activity, averaging 28 flights per year, the Shuttle would barely compete with the Titan III even on a straight dollar-for-dollar basis, without discounting. The Shuttle would save only half a billion discounted dollars, and would break even with the Titan III at a discount rate of only 1.5 percent. This was as if a Las Vegas hotel and casino, a speculative venture if ever one existed, were to try for a loan with interest at 1.5 percent. If the Shuttle had to do this, it would not fly.

Its prospects, however, improved markedly at the highest activity level of 55 flights per year. Now the Shuttle would break even at a discount rate of nine percent, encouragingly close to the BoB requirement that the Shuttle justify itself at a 10 percent discount rate. True, this projection raised the question of whether it was anything more than blue sky and hype, for it would call for doubling the recent Air Force activity level. Much of that activity had involved the launch of large numbers of Corona reconnaissance satellites, which were about to give way to the far more capable Big Bird spacecraft — with Big Bird flying in much-reduced numbers. Nevertheless, under these BoB ground rules, it was clear that the best way to justify a shuttle program was to project the largest possible number of operational flights. [Budget Bureau, “NASA Issues Paper,” August 1969: attachment, “Space Transportation System,” August 22, 1969.]

The Bureau’s analyses carried a thoroughness that could put a tax audit to shame. Nevertheless, its analysts would give NASA full opportunity to argue in favor of the Shuttle, and particularly of the two-stage fully-reusable configuration that now was this agency’s heart’s desire. In doing this, the BoB would repeat the experience of 1969. Its director, Robert Mayo, had given Paine free rein to develop the post-Apollo plan of his dreams and even to see it endorsed by the Space Task Group, largely without change. Then Mayo had lowered the boom, cutting NASA’s budget and putting that plan out of reach. His colleagues now were ready to give NASA similar leeway during the studies of 1970, amid a general awareness that their budget axe was close at hand.

Robert Lindley, an engineering director at NASA Headquarters in Washington, held the initial responsibility for studies of shuttle economics. Though he was well aware that the Shuttle would have to make its living by providing low-cost space transportation, he appreciated that even this might not be enough. President Nixon’s budget for FY 1971, which went to Congress early in 1970, provided $125 million for procurement of expendable launch vehicles. This was 3.7 percent of the total request of $3.333 billion and offered a useful estimate of the amount NASA might have saved that year if it already had a shuttle. This was not an aberration. The nuclear physicist Ralph Lapp, a Manhattan Project veteran and a leading critic of the Shuttle, would shortly note that during the eight years of 1964-1971, procurement of expendables had cost an average of some $130 million per year, or 2.9 percent of NASA’s cumulative budgets. [Letter, Paine to Shultz, September 1, 1970; U.S. Senate Committee on Aeronautical and Space Sciences, Hearings, FY 1973, pp. 1079-1086.]

NASA certainly was not going to justify the Shuttle on such a basis, particularly since these minimal savings would fall much further in present value through use of the 10 percent discount rate. It was not clear how to invent additional savings, and some officials were willing to conjure them out of little more than thin air. Dale Wyatt, an assistant administrator, put his hope in the fact that just then, in early 1970, the shuttle still held close links to the space station. He assumed that the nation and not just NASA would need this station. He further assumed that it would demand logistic support at the rate of a resupply mission every two weeks. If those missions were to use conventional expendables, including an enlarged Gemini capsule for the crews, they would cost $1.625 billion per year. If, however, they were to use the Shuttle, their cost would drop to $480 million. Thus, out of his assumptions, Wyatt came up with savings of over a billion dollars per year, more than enough to justify shuttle development. [Wyatt, memo, “Cost Effectiveness of the Shuttle,” February 12, 1970.]

This, however, represented a retreat toward viewing the Shuttle once again as a vehicle for use in space station logistics. During 1969, the Shuttle had gained considerable headway through a different approach, which had presented it as the linchpin of a program of automated rather than of piloted spacecraft. Lindley saw that he could provide a more convincing justification by extending this approach. He asserted that the Shuttle could achieve additional cost savings not only by reducing launch costs, but by cutting the cost of the payloads themselves.

Lindley proposed that the availability of such inexpensive payloads could stimulate new uses for space, encouraging satellite contractors to build more such spacecraft. The Shuttle could thus promote the growth of its own traffic, for it would carry not only the planned payloads of 1970 but many others besides. The Shuttle then might repeat the experience of commercial aviation, which had achieved vast growth by cutting the prices of its passenger tickets.

How could the Shuttle achieve such “payload effects?” It would do this by completely revamping standard practice in satellite design and development. The spacecraft of 1970 faced stringent limits on weight and volume, imposed by the restricted capacities of that era’s launch vehicles. Because there was no way to recover a failed satellite for study, much effort went into extensive ground tests that could assure reliability. Quality assurance demanded extensive documentation, to assure that engineers could use limited data from telemetry to trace and recreate the cause of an in-flight failure. To cope with such a failure, the project staff had to remain on call, drawing salaries all the while. A large technical staff would also be necessary to assure success, conducting extensive pre-launch checkouts and then working with the spacecraft after it reached orbit.

The Shuttle offered a completely different outlook. Already its capacious payload bay was promising to ease restrictions on weight and volume. To Lindley, this meant that the electronics of future spacecraft might be packaged in modules mounted in racks, having standard connections for power and data. Like the cockpit instruments of Pan Am with their provisions for onboard fault detection, these modules would indicate their health to the Shuttle flight crew.

Synchronous Equatorial Orbiter (SEO): A Medium-Size, Semi-Complex Payload Operating in Synchronous Equatorial Orbit The concept of payload effects. The large volume and payload capacity of the shuttle’s cargo bay made it plausible that spacecraft might cut cost by relaxing constraints on weight and size. (NASA) |

Satellite checkout would occur after reaching orbit, not on the ground. Astronauts would locate problems using the satellite’s fault detection system, removing faulty modules and replacing them with spares. A satellite also would incorporate other systems: solar panels, power conditioning, attitude control, and data and telemetry. These could also receive on-orbit checkout. In addition to this, because they would provide standard functions, they could be built to standardized designs. They would take shape as additional modules, listed in a catalog.

Existing practice called for new spacecraft to have new subsystems in all these areas, designed from scratch and meticulously tested. The use of standard subsystems, however, would turn satellite design into an exercise in choosing and assembling these off-the-shelf components. They would usually demand more weight, volume, and power than custom versions, but would offer great cost savings through their standardization. Other savings would accrue through the Shuttle’s low cost per flight. When a spacecraft began to fail after years of service, a shuttle mission could refurbish and restore it for a fraction of the cost of a replacement. [Low, Personal Notes No. 16, March 28, 1970; Report LMSC-990594 (Lockheed); Astronautics & Aeronautics, June 1972, pp. 50-58.]

Lindley’s work received an attentive audience at the BoB, where Mayo wrote a letter to Paine in mid-March that called for NASA to prepare a detailed economic analysis of the Shuttle. Mayo accepted that payload effects represented a promising route toward justifying the Shuttle, and called on Paine to conduct a study that would define their cost savings. He also urged NASA to compare the merits of four alternative programs:

1. Full scale development of a fully reusable space shuttle.

2. Develop a hybrid system with a reusable spacecraft and expendable booster.

3. Develop a fully expendable low-cost launch system.

4. Continue to rely on the current family of launch vehicles or improved versions of these vehicles.

Mayo wanted estimates of the expected potential demand for payloads in orbit, with the understanding that payload effects could increase this demand. He wanted estimates of the cost of development of his four alternatives. Finally, he requested calculation of the discount rate for each alternative, equivalent to a rate of return. He described this as “the discount rate which equates the annual benefits to the annual program costs through 1990.” He added in his cover letter that “we request general use of a 10 percent discount rate”; it was up to Paine to show that the Shuttle could achieve this. [Letter, Mayo to Paine, March 18, 1970.]

NASA was to conduct the analyses in-house while working with a BoB staff member, Earl Rhode. Though Lindley was the man in charge, it soon became clear that he was getting in over his head. Joseph McGolrick, a manager of advanced programs, later recalled what happened:

Lindley had this group of people from all over Headquarters, and he was drawing from people their estimates of “How much could be saved?” He was an extremely charming and extremely shrewd man who was getting out of this group of people a set of numbers for what the economics of the shuttle might be downstream. I mean, people would object about “This is not knowable, or if it is knowable, we don’t have the information yet; we would have to do a study.” But he really charmed them and said, “Hey, you know, let’s just get an estimate.”

It was obvious to me what he was doing was focusing, steering this group of Headquarters people into a totally subjective, qualitative kind of justification of the shuttle, without any real basis at all. And he went through about four or five iterations of this thing, finding out where the critical problems were, and finding solutions to these little problems. [The] problems, from their point of view, in justifying the shuttle. [John Mauer interview, Joseph McGolrick, October 24, 1984, pp. 22-24.]

Lindley knew that he needed more than arm-waving. He required an assessment of payload effects by an aerospace corporation with actual experience in building spacecraft. He wanted “mission models,” projections of the specific spacecraft, and payloads that the shuttle might carry, and he needed such mission models for the Air Force as well as NASA. The BoB also encouraged him strongly to have the economic analysis — including the vital determination of discount rates — conducted by professional economists with experience in this area.

He proceeded to set up a series of studies. For mission modeling and for payload and launch vehicle cost estimates, he turned to the Aerospace Corp., which had strong ties to the Air Force and was widely known as a center of expertise. Lockheed, builder of the Corona spacecraft, took charge of work on payload effects. For the overall economic evaluation, which these other contracts would support, Lindley followed recommendations from the BoB and approached the firm of Mathematica, Inc., in Princeton, New Jersey.

Mathematica was the lengthened shadow of its founder, the economist Oskar Morgenstern. Expelled from a professorship at the University of Vienna following the Nazi occupation in 1938, Morgenstern had taken a post at Princeton’s Institute for Advanced Study, where he proceeded to work with John von Neumann, one of the world’s leading mathematicians. Together they developed the theory of games, which provided mathematical analysis of situations where competitors act independently and with conflicting interests, while influencing one another’s actions. Their book of 1944, Theory of Games and Economic Behavior, became a landmark. In turn, its mathematical methods proved applicable not only in business and economics but in military planning and nuclear arms negotiations. Morgenstern set up his firm of Mathematica to pursue such applications. [National Journal, March 13, 1971, p. 540; August 12, 1972, p. 1292; Report LMSC-A990594 (Lockheed), p. 1-1; Blaug, Economists, pp. 172-174; New York Times, February 13, 1977, Section 3, pp. 1, 9.]

In addition to analysis that might justify NASA’s Shuttle, BoB officials also wanted further studies of alternate shuttle configurations. Though NASA might be ready to push ahead at full speed with a detailed study of two-stage fully-reusable designs, as early as February 1970, agency officials assured industry representatives that NASA would pursue other concepts as well. These might offer lower development cost, or reduce the outlays in the near term.

In mid-May, NASA awarded the main Phase B contracts to North American Rockwell and McDonnell Douglas. The chairman of Grumman, a losing bidder, responded with a vigorous protest. In phone calls and meetings with NASA officials, he stated that he opposed NASA’s preferred shuttle concept, that the Request for Proposal had been faulty, and that NASA’s decision was tantamount to declaring that Grumman would have to get out of the business of piloted space flight. He also complained that Grumman lacked strong support from the senators of New York, its home state, and that the company’s top executives lacked rapport with their NASA counterparts. Paine’s colleagues responded in kind, noting that selection of contractors was not a popularity contest and adding, frankly, that in its technical aspects, Grumman’s proposal had been the worst of the four received.

At the same time, NASA was ready to supplement the main Phase B contracts with additional Phase A studies of alternatives. Grumman walked away with the largest of these, funded at $4 million. This company had a strong background in piloted space flight, having built the lunar module that had carried Apollo astronauts to the moon’s surface. Grumman did lack experience, however, with large rocket stages. Its management redressed this deficiency by teaming with Boeing, which had designed and built the first stage of the Saturn V. This team was potentially as strong as that of North American Rockwell or McDonnell Douglas.

The Grumman/Boeing alternatives included the use of expendable propellant tanks, in the fashion of Lockheed’s Star Clipper. They also included several approaches to phased development, whereby an initial version of the Shuttle would fly with interim systems. Rather than use the SSME for the main engines of both stages, a two-stage fully reusable shuttle might use a different engine, Rocketdyne’s J-2S. This was a simplified version of the standard J-2, with its thrust increased to 265,000 pounds. Though, at 14,030 feet per second, its exhaust velocity would not match that of the SSME, it still was 2.6 percent higher than that of the standard J-2, representing a modest but useful increase.

A more far-reaching approach to phased development called for the initial use of an expendable booster. This could be a Saturn V first stage; it also might be a large new stage using solid propellant. This approach would allow NASA to delay the development of a reusable shuttle first stage while allowing the stage that counted — the orbiter — to enter initial service. [Low: Personal Notes No. 22, May 16, 1970; No. 23, May 19, 1970; Rocketdyne, Expendable Launch Vehicle Engines; Aviation Week, June 22, 1970, p. 257.]

Two other companies also received Phase A contracts, each worth $1 million. Lockheed was to study new versions of Star Clipper, including a variant that might fly as a second stage atop the reusable booster of McDonnell Douglas. The second such contractor, Chrysler Corp., had operated since the early 1950s as Wernher von Braun’s manufacturing arm and had built most of the first stages of the Saturn I-B. Its alternative shuttle concept was strange indeed, with a reusable first stage powered by Rocketdyne’s aerospike engines and shaped like an enormous Apollo capsule. Though it was definitely a wild card in NASA’s deck, it showed that even at this late date, Paine was still willing to look at concepts that did not reflect the views of Max Hunter or Max Faget. [Aviation Week, June 22, 1970, p. 96; Jenkins, Space Shuttle, pp. 96-100.]

Shuttle concept of Chrysler Corporation. Left, as a booster stage with a conventional shuttle orbiter. Right, cutaway view, which allegedly could carry payload to orbit. (Art by Dennis Jenkins) |

The following is a summary of the studies that were under contract by mid-1970. [“NASA Space Shuttle Studies,” summary, April 16, 1971.]

Phase B – Fully Reusable Space Shuttle

North American Rockwell: $8 million (later, $10.8 million)

McDonnell Douglas: $8 million (later, $10.8 million)Phase B – Space Shuttle Main Engine

Pratt & Whitney: $6 million

Rocketdyne: $6 million

Aerojet General: $6 millionPhase A – Alternate Space Shuttle

Grumman/Boeing: $4 million

Lockheed: $1 million

Chrysler: $1 millionEconomic Studies and Analysis

Aerospace Corp.: Payloads and launch costs, $1,625,000

Lockheed: Payload effects, $399,000

Mathematica: Cost-benefit analysis, $400,000

The Phase B contracts, initially totalling $34 million, reflected NASA’s hope that the detailed study of vehicle and engine designs could lead relatively quickly to award of contracts for Phase C and D, covering mainstream design and development. NASA would fulfill this wish for the SSME by granting its development contract to Rocketdyne in July 1971. The agency hoped to choose a single main contractor for the Shuttle itself soon afterward.

Under the spur of questions from the BoB, however, NASA now would give the Shuttle an unusually close level of scrutiny. Its economic analysis would go beyond standard cost-benefit analysis, with its emphasis on discounted cash flows, by introducing the new topic of payload effects. This topic, with its promise of sweeping changes in methods of satellite development, promised to broaden anew the significance of the Shuttle. Studies of alternative designs would go beyond the earlier issue of reducing development cost while accepting higher operational cost. These studies would now include phased development, with the prospect of treating the shuttle effort as three separate projects — booster, orbiter, SSME — that might go forward in a sequence rather than simultaneously. The resulting program stretchout then might allow NASA to proceed with the Shuttle while fitting its year-to-year costs within a tight budget ceiling.

Change at NASA and the Bureau of the Budget

Tom Paine, who had been reporting to James Webb as Deputy Administrator during much of 1968, took over as Acting Administrator following Webb’s resignation that October. During 1969, as Paine became full Administrator, he served without a deputy. In September, he moved to remedy this situation by recommending George Low for that post. Low, who had been managing the Apollo spacecraft program at NASA’s Manned Spacecraft Center, started work as Paine’s deputy in December. When Paine left NASA in September 1970, Low became Acting Administrator in his turn. [Press release, White House, November 13, 1969; Low, Personal Notes No. 1, January 1, 1970.]

George Low. (NASA) |

The BoB saw considerably more far-reaching changes that grew out of a revamping within the Executive Branch. Nixon had a strong interest in management and policy development; in April 1969, he set up an advisory council to recommend changes within the White House that could enhance its effectiveness in these areas. During the following year, his personal experience stimulated his desire for change. As Vice-President under Eisenhower, and now as President, he had worked with the National Security Council (NSC), which had dealt in an orderly fashion with contrasting recommendations from the Pentagon, the State Department, and the intelligence agencies. Nixon felt the lack of any similar institution to coordinate policy in domestic affairs.

In March 1970, he announced his decision. He would set up a Domestic Council within the White House, as a Cabinet-level counterpart of the NSC. Its membership would include the Vice-President as well as nine Cabinet secretaries. Nixon chose his assistant John Ehrlichman to direct it, thus giving him power on a par with that of Henry Kissinger, the National Security Advisor and head of the NSC.

Nixon also proposed to reorganize the BoB, to strengthen an emphasis on management while enhancing its activity in program evaluation and coordination. The BoB would also receive a new name: the Office of Management and Budget (OMB). In Nixon’s words, “The Domestic Council will be primarily concerned with what we do; the Office of Management and Budget will be primarily concerned with how we do it, and how well we do it.”

The BoB had long since established itself as an elite group within Washington. Its responsibilities covered the whole of the federal budget, with its myriad of programs and agencies. Yet the BoB staff rarely numbered more than 550, with some 350 being professionals, many with two or more college degrees. They stayed away from the media; they were not a good source of leaks. Veteran staffers, proud of the BOB’s small size and central responsibilities, viewed themselves as unique. They said that if an army of Martians marched on the Capitol, while everyone would flee to the hills, the BoB staff would stay behind and prepare for an orderly transition in government.

Robert Mayo, head of the BoB, did not stay on. He had worn out his welcome by interceding in the shaping of the Pentagon budget, which Nixon had sought to develop through talks with only Henry Kissinger, the Joint Chiefs, and the Secretary of Defense. John Ehrlichman would recall that “Nixon felt that he understood enough of the general budget process that he didn’t need Mayo. Nixon just froze him out. And he also just plain didn’t like Mayo.”

The new OMB had plenty of clout. Mayo’s successor, George Shultz, had been Nixon’s Secretary of Labor. After taking over as head of the OMB, he received an office within the White House itself. He started work on July 1, 1970, the day the OMB formally came into existence, and quickly emerged as one of Nixon’s closest intimates.

“I think he has the most important position in government,” AFL-CIO president George Meany said in late August. “He is, in my book, the executive vice president of the corporation. In other words, he is the guy who runs the corporation from day to day. He is without question over all the Cabinet members. They are just department heads under him.” In January 1971, National Journal reported that “Shultz sees and communicates with Mr. Nixon on official business more than any other senior White House aide. Several times a day he is summoned to the President’s oval office; the two talk by phone frequently. He regularly receives memoranda from the President with the notation penned in the margin, ‘What do you think, George?’” [Berman, Office, pp. ix-x, Chapter 5; National Journal: March 21, 1970, pp. 620-626; January 23, 1971, pp. 151-165; June 12, 1971, pp. 1235-1244; December 13, 1975, pp. 1690-1691; John Logsdon interview, John Ehrlichman, Santa Fe, New Mexico, May 6, 1983, pp. 17-18.]

For NASA, during the summer and fall of 1970, the immediate matter at hand was the budget for FY 1972. On August 7, Shultz sent a letter to Paine that set a target of $3.215 billion in outlays, representing a further cut from the already much-reduced level of FY 1971. Low responded on September 30, replying: yes, we could meet this mark with additional cancellations, including termination of NERVA and scrapping plans for Apollo 17. He would much prefer, however, an outlay of $3.411 billion. “We strongly advise against the actions that would be required to achieve the target level,” he concluded. [Letters: Shultz to Paine, August 7, 1970; Low to Shultz, September 30, 1970.]

Subsequent exchanges with the OMB did not go well. In late November, Low hosted a meeting at his home to discuss what to do next. Participants included Dale Myers, head of the Office of Manned Space Flight, and Charles Donlan, head of the Space Shuttle program. As Low noted in a personal memo, a few days later:

We held the meeting because of our collective concern that the shuttle program, as now constituted (two-stage fully reusable vehicle), would probably cost more than we could afford on an annual basis in the middle of the ’70s. A phased program, wherein we would first procure only the orbiter and launch it on a modified S-IC stage [the first stage of the Saturn V] and only subsequently build a booster, would make more sense from the point of view of annual funding. It might also make more sense technically because we would face only one major problem at a time. At the same time, we could also adopt a Block I/Block II approach, wherein many of the “nice to have features” would be reserved for Block II and would not be incorporated into Block I. [Low, Personal Notes No. 36, November 28, 1970.]

On December 7, late in the evening, Low received a phone call from Donald Rice, an OMB assistant director. Rice said that NASA would receive outlays of $3.206 billion, less than Shultz’s mark of four months earlier, with new obligational authority of $3.283 billion. The latter represented the request for appropriations that Nixon would send to Congress. Apollo 17 remained in the budget, while NERVA would survive with support from key senators. The Shuttle, however, took a heavy hit.

Low still hoped to receive approval to proceed with shuttle development during FY 1972. Four days later, he sent Rice a letter proposing language for a formal statement on shuttle policy:

The FY 1972 budget provides for proceeding with the development of a space shuttle system.

Detailed design and development of the shuttle engine — the longest lead time component — will be begun in FY 1972.

Airframe design and development will proceed on an orderly step-by-step basis leading to detailed design or initiation of development during FY 1972 depending on progress in studies now underway.

Rice sent this letter down through channels to Daniel Taft, an OMB staffer who worked with this issue. Taft replied with his own letter to Rice, noting that Low was proposing that “the Administration has approved proceeding with the space shuttle system.” Taft continued:

We recommend that the Administration preserve flexibility by:A. Making no commitment to proceeding with the development of the entire shuttle system.

B. Making no commitment to an FY 1972 decision on initiation of development of the airframe.

Taft added a draft of a letter with which Rice replied to Low. While Rice agreed to proceed with development of the SSME, he made no such commitment to the Shuttle itself. This had obvious potential for an embarrassing situation wherein people would regard a commitment to the engine as a back-door commitment to the shuttle. The SSME therefore received the provisional name of Advanced Space Engine, with the understanding that it might power a new low-cost expendable launch vehicle instead. [Low, Personal Notes No. 37, December 20, 1970; letters: Low to Rice, December 11, 1970; Taft to Rice, December 15, 1970; Rice to Low, December 17, 1970; Niskanen to Rice, December 26, 1970; Taft to Rice, January 8, 1971.]

Rice’s phone call of December 7 did not mark the end to the budget negotiations. In Nixon’s formal budget, late in January, NASA received another cut. It now was slated for $3.271 billion in new obligational authority. The only hopeful note was that at least this matched the $3.269 billion appropriated for FY 1971, with no allowance for inflation. NASA, however, was to set aside over $100 million of this to spend in future years; its outlays were to total only $3.152 billion.

In initial discussions, NASA had sought $220 million for the Shuttle. A preliminary review at OMB had cut this to $195 million. In a subsequent review, however, the OMB swung its budget axe much harder, chopping the final number to $105 million, or $100 million in budget authority. This included $35 million for studies of the orbiter and booster along with $44 million for engine development. The space station was still alive within the FY 1972 budget and would receive $15 million, to cover continuing studies. While the shuttle was healthier than the station, it now would be on hold for another year. [Low, statement, January 28, 1971; letter, Shultz to Low, February 19, 1971; Aviation Week: January 25, 1971, p. 13; February 1, 1971, pp. 18-19.]

The Administration’s intention to keep NASA on a tight leash was reemphasized as the agency received a new Administrator, James Fletcher. Fletcher had been president of the University of Utah. While his predecessor, James Webb, had spent much of his career as a high-level Washington apparatchik, and while Tom Paine had been a research manager at General Electric, James Fletcher brought hands-on experience in aerospace development. During the 1950s, he had headed a guidance-system group at the firm of TRW when that company had provided a technical staff that had managed the development of the Air Force’s major missiles: Atlas, Titan, Thor, and Minuteman.

James C. Fletcher, NASA Administrator, 1971-1977. (NASA) |

The aerospace industry was well aware of the leadership that had come out of the Navaho missile program at NAA: NASA’s Dale Myers, Paul Castenholz of the SSME, and Sam Hoffman who had been president of Rocketdyne. TRW had produced leadership that was even more stellar, for this company’s Air Force work had placed it at the center of the nation’s most important military efforts.

George Mueller had been a TRW manager before coming to NASA. Other TRW alumni included Richard DeLauer, who became an under-secretary of defense; Louis Dunn, who had headed the Jet Propulsion Laboratory; Ruben Mettler, who stayed at TRW and became its chairman and chief executive; George Solomon, who went on to serve as TRW’s executive vice-president; and Albert Wheelon, who pushed the development of the Big Bird reconnaissance satellite within the CIA, and later became chairman of Hughes Aircraft. [Heppenheimer, Countdown, pp. 80, 149, 259; Ramo, Business, p. 102.]

Having served amid such company, Fletcher’s pedigree was sterling. To Nixon’s colleagues, however, he was merely a man who might help NASA toe the line. In February 1970, Peter Flanigan of the White House asked his staffer Clay Whitehead to prepare a memo on the subject of NASA, which Flanigan sent over to Ehrlichman:

This Administration has never really faced up to where we are going in Space. NASA, with some help from the Vice President, made a try in 1969 to get the President committed to an “ever-onward-and-upward” post-Apollo program with continuing budget growth into the $6-10 billion range. We were successful in holding that off at least temporarily, but we have not developed any theme or consistency in policy. As a result, NASA is both drifting and lobbying for better things – without being forced to focus realistically on what it ought to be doing….

NASA is — or should be — making a transition from rapid razzle-dazzle growth and glamor to organizational maturity and more stable operations for the long-term. Such a transition requires wise and agile management at the top if it is to be achieved successfully. NASA has not had that. (Tom Paine may have had the ability, but he lacked the inclination – preferring to aim for continued growth.) They have a tremendous overhead structure, far too large for any reasonable size space program, that will have to be reduced….

We need a new Administrator who will turn down NASA’s empire-building fervor and turn his attention to (1) sensible straightening away of internal management and (2) working with OMB and White House to show us what broad but concrete alternatives the President has that meet all his various objectives. In short, we need someone who will work with us rather than against us, and will seek progress toward the President’s stated goals, and will shape the program to reflect credit on the President rather than embarrassment….

We really ought to decide if we mean to muddle through on space policy for the rest of the President’s term in office or want to get serious about it. [Memo, Whitehead to Flanigan, February 6, 1971. Reprinted in NASA SP-4407, Vol. II, pp. 50-52.]

The Fall of the Two-Stage Fully-Reusable Shuttle

Mayo’s letter of March 18, which directed Paine to compare the merits of four alternatives, set a date of May 1 for an interim report. With a week to spare, Lindley concluded that economic criteria showed that the fully-reusable shuttle was best. It would cost the most to develop, but even when using discounted dollars, its low cost per flight would yield the largest savings. The report ranked the other choices in order: a new low-cost expendable booster, a partially reusable shuttle, and continued use of current expendables. In sum, NASA’s preferred design offered the greatest advantage, but anything would be better than the expendables that represented current practice.

This interim report impressed officials at the OMB; it also drew favorable attention at Mathematica. Early in July, representatives from that firm met with counterparts from NASA and OMB. Pending further study, initial results from Mathematica’s analysis proved to agree with those of Lindley’s interim report. In mid-August, NASA sent a second report to OMB, in which the ranking of the alternatives again was unchanged. This new report asserted that payload effects would lead to larger savings than reduction in launch costs. In a bold ploy to remove the bothersome distraction of alternate designs, the report presented the fully-reusable Shuttle as the ultimate goal. Therefore, the “hybrid (partially reusable shuttle) has been dropped from contention.”

The next nine months, from August 1970 to May 1971, were a time of preparation. NASA carried through the negotiations with OMB that defined the budget for FY 1972, while proceeding with arrangements for award of the SSME development contract. The studies of 1970 went forward: Phase B for the fully-reusable Shuttle and main engine, Phase A for alternative designs. The economic analyses also went ahead. In turn, the OMB strengthened its hand by bringing in an economist, John Sullivan, to review the analysis of Mathematica. Then during May and June, a flurry of contractor reports presented the most extensive work to date on the Shuttle design and its economics. If NASA was to win over the skeptics at OMB, these reports would be the key. [Letter, Mayo to Paine, March 18, 1970; NASA interim report, “Alternate Systems for Reducing the Cost of Payload in Orbit,” April 24, 1970; memo, Rhode to Young (OMB), July 23, 1970; NASA report, “Economic Analysis: Alternate Systems for Reducing the Cost of Payloads in Orbit,” August 15, 1970; NASA, “Documentation of the Space Shuttle Decision Process,” February 4, 1972.]

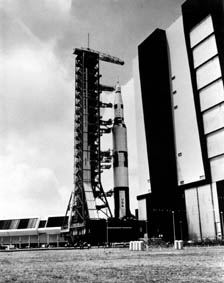

Designers expected to launch the Shuttle using the Apollo facilities at Cape Canaveral. Those facilities were alive with activity during 1971. Visitors came away with a strong conclusion: This is not the delicate precision of a laboratory; this is heavy industry. The centerpiece was the Vehicle Assembly Building, one of the largest structures on the planet, with nearly eight acres under roof and an enclosed volume of close to five million cubic yards. It had four bays, each with a door as tall as a 45-story office building, and each able to accommodate a complete Saturn V — or a shuttle.

Saturn V on its launch platform with tower, aboard an enormous tracked vehicle as it exits the VAB. NASA expected to use these facilities and equipment in launching the shuttle. (NASA) |

When launching a shuttle, work crews would begin with the booster, longer than a Boeing 747 and considerably fatter in the fuselage. They would swing it to an upright position and mount it to a Launch Umbilical Tower, a massive steel platform carrying a red-painted tower with arms that would connect to the shuttle. Next, an orbiter would go onto the booster’s back. A crawler, a diesel-powered vehicle weighing 3000 tons, then would move beneath the platform and lift it to ride atop a flat surface the size of a baseball infield.

Eight tractor treads would begin to clank, each 40 feet long and 10 feet high. The entire array — crawler, platform, tower, booster, orbiter — would make its way through the immense door. The crawler would proceed down a roadway paved with crushed rock and resembling an interstate highway, with two sets of lanes divided by a median. That entire roadway, however, would serve the crawler alone, with those divided sections accommodating the crawler’s widely-separated treads. The crawler would head for a launch pad, three miles away, and in this fashion the Shuttle would set out for orbit at the speed of those treads — one mile per hour.

Fueled and cleared for launch, the Shuttle would thunder into the air with the thrust of 12 SSMEs in the base of the booster. The orbiter would separate and fly onward, propelled by its own SSMEs. The booster, empty of fuel, would come down through the atmosphere and return to a runway at the Cape, with power from up to 12 jet engines. After completing its mission in space, the orbiter would reenter and land on the same runway. Preparations for the next flight, covering both the booster and orbiter, would take as little as two weeks. [Heppenheimer, Countdown, p. 224; Jenkins, Space Shuttle, pp. 86-94; Aviation Week, June 7, 1971, pp. 55-61; AIAA Papers 71-804, 71-805; Reports MDC E0308 (McDonnell Douglas); SD 71-114-1 (North American Rockwell).]

North American Rockwell and McDonnell Douglas both presented estimates for the development costs of their shuttles, and for operational costs. Analysts at the Aerospace Corp. prepared separate estimates, which fed into the economic studies of Mathematica. These projected $9.92 billion for shuttle development along with a cost per flight of $4.6 million. The latter number represented “marginal cost,” which would pay for one additional shuttle flight once the system was up and flying routinely. It was less than the cost of a Delta expendable vehicle, $5.4 million. While a Delta could carry some 5000 pounds to orbit, the shuttle would carry 65,000. This capacity would show a substantial increase over the 40,000 pounds of a Saturn I-B, with this Saturn showing a cost per flight of some $55 million. Hence, if all went well, the Shuttle indeed would cut the cost of space flight by an order of magnitude. [Report ATR-72 (7231)-1 (Aerospace Corp.); AIAA Paper 71-806; Jenkins, Space Shuttle, p. 125.]

The Aerospace Corp. received wish lists from NASA, the Air Force, and from the commercial Communications Satellite Corp., describing the payloads these agencies hoped to launch during the years 1978-1990. It is difficult to characterize those payload lists as reflecting more than wishes, for while these agencies had some sense of what they hoped to do during the 1970s, the 1980s were too far off for serious attention. Nevertheless, although NASA and the Pentagon were subject to year-to-year funding approvals, their planners blithely proceeded to describe what they hoped to be doing some 20 years in the future.

The ensemble of these lists defined a baseline mission model, with each individual payload described in at least an introductory fashion. Each payload had an estimated weight which Aerospace Corp. analysts used as a basis for work that would compare the Shuttle to alternatives calling for expendable launch vehicles. Based on its weight, each payload could be assigned to a particular rocket having a known launch cost, such as a Delta or Titan III. These analysts also determined a cost for each payload by using “cost estimating relationships,” which drew on historical data. These relationships gave good approximations of the actual costs of existing spacecraft and satellites, which served as benchmarks.

In treating shuttle payloads, payload effects were at the forefront. Lockheed selected four spacecraft, three being satellites that together spanned a broad range of sizes and the fourth being a Mars orbiter. Company engineers examined these spacecraft in considerable detail, at the level of subsystems. They then prepared a design guide for low-cost shuttle payloads, which would emphasize minimal weight and volume constraints, modular electronics and subsystems, and on-orbit checkout and refurbishment. The Aerospace Corp. then used this Lockheed work to derive new payload cost and weight estimates, redefining the entire baseline mission model in the light of payload effects. This baseline mission model thus called for 736 shuttle flights during 1978-1990, or some 57 flights per year. [Reports ATR-72 (7231)-1 (Aerospace Corp.); LMSC-A990556, -A990558 and -A990594 (Lockheed); Astronautics & Aeronautics, June 1972, pp. 50-58; AIAA Paper 73-73.]

The Aerospace analysis also presented year-by-year costs for both payloads and launch vehicles, treating three alternatives: a fully-reusable shuttle, a new low-cost expendable booster, and the continued use of existing expendables. These covered three of the four alternatives that Mayo had presented to Paine in his letter of March 18, 1970. The fourth alternative, a hybrid or partially-reusable shuttle, was not treated, a point that would not escape the attention of the OMB. Aerospace Corp. presented its findings in undiscounted dollars, leaving the discounted cash-flow analyses to Mathematica. Even so, these findings were valuable, and revealing (table below).

COSTS OF THREE SPACE PROGRAMS (in millions of dollars):

| . | Current Expendable | New Expendable | Fully Reusable Shuttle |

| . | |||

| Expected Launch Vehicle Costs | |||

| Research and development | $ 960 | $ 1,185 | $ 9,920 |

| Facilities and fleet | 584 | 727 | 2,884 |

| Total incurring costs | 1,544 | 1,912 | 12,804 |

| Launch-by-launch recurring costs | 13,115 | 12,981 | 5,510 |

| Total launch costs | $14,659 | $14,893 | $18,314 |

| Expected Payload Costs | |||

| Research and development | 12,382 | 11,179 | 10,070 |

| Production and recurring costs | 31,254 | 28,896 | 15,786 |

| Total payload costs | 43,636 | 40,075 | 25,856 |

| Expected total space program costs (Aerospace Corporation) | $58,295 | $54,968 | $44,170 |

Current expendables would also require funds for research and development, to enhance their capabilities. Their launch facilities would receive their own enhancements. Nevertheless, even with an extraordinarily generous mission model and with undiscounted dollars, the Shuttle would fail to pay its way — if one considered launch costs only. The large size of the mission model would amplify the substantial difference between recurring launch costs of the Shuttle versus those of expendables. Still the high cost of shuttle development and procurement, some $12.8 billion, would swamp these savings derived from lower launch costs, to give the current expendables a strong advantage.

Payload effects promised to change this picture dramatically. These effects promised modest but welcome reductions in the cost of payload research and development. They also promised savings of some 50 percent in payload recurring costs, which represented the largest single item in all three space programs. As a consequence, when one extended the comparisons to include payload costs and not merely launch costs, the Shuttle-based space program gave a projected saving of as much as $14 billion when compared to a program based on current expendables.

A year-by-year comparison showed that the Shuttle would operate at a strong financial disadvantage between 1971 and 1977, for it would incur its cost of development during those years. As early as 1979, however, the Shuttle-based program would show a billion-dollar saving in annual outlays, due to payload effects as well as lower launch costs. That advantage would top $2 billion per year during most of the following decade.

Economic justification for the shuttle. The dotted area at left, 1971-1977, represents cost of shuttle development. The much larger hatched area at right, 1978-1990, represents cost savings alleged to be achievable by using the shuttle. (Mathematica Corporation) |