| by Dave Fischer

We have had several queries concerning “pintle injectors” (make sure you read the last paragraph of this post), as these are mentioned in the Space-X page on the Falcon 9, where it refers to the Merlin rocket engine and the “pintle style injector”:

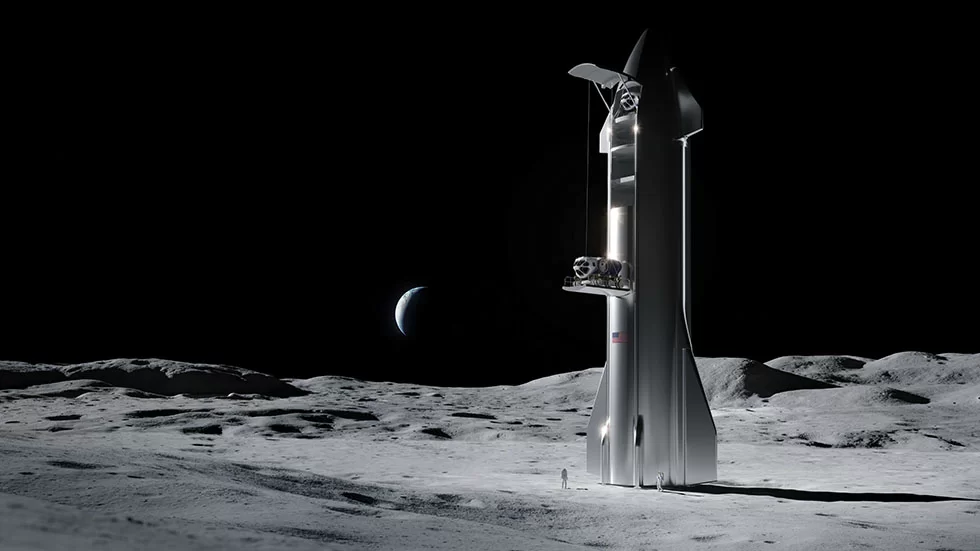

Based on the queries and the Space-X information, we went sleuthing. First, we came across the fact that TRW built the LEM descent engine, which used the pintle injector. We ran across David Meerman Scott’s blog apolloartifacts for a discussion and look at a model of the famous Lunar Module Descent Engine (LMDE). The engine was made famous by the Apollo 13 mission, where:

In 2000, TRW demonstrated the TR-106 engine (pintle injector) using LOX / LH2 at NASA’s John C. Stennis Space Center . The engine generated 650,000 pounds of thrust, more than the 400,000 pounds of thrust generated by the Space Shuttle Main Engine SSME. Al Frew, vice president and general manager, TRW Space & Technology Division stated:

Despite the promise the motor demonstrated, NASA canceled further work. The pintle injector engines have a long history in the former Soviet Union. The NK-33 was the successor to the NK-15 engines used in the failed Soviet N1 Moon launcher. NK-33 have been used with the Russian Proton launch system. An interesting discussion of the Soviet Moon rocket, its engines and the NK-33 successor can be found here, along with spectacular video of the launch and explosion. Orbital Sciences has now contracted with Aerojet (owner of the NK-33 engines) to finish developing and testing the NK-33 engines, now designated as AJ26-58 for the Taurus II. |

| Jonathon Goff, at Masten Space Systems, had a commentary at Selenianboondocks on the 2006 Space-X change from an ablative Merlin engine to a regenerative engine. Jon states that the “engine related problems are interrelated, and that they have to do with the combination of using a high chamber pressure engine design with a pintle-injector and an ablatively cooled chamber wall.” That is, the flame produced by the cone of fuel and oxidizer hits the wall of the chamber and overheats the wall.

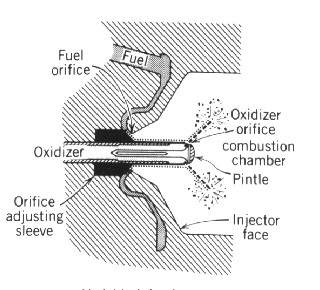

Included in the commentary is a simplified image of a pintle injector rocket engine, which illustrates the flow of liquid oxygen and fuel (RP-1 or liquid hydrogen) through the pintle injector into a cone shaped spray in the combustion chamber. The replacement of the ablative chamber with a regenerative chamber eliminates the overheating. |

Pintle Injector Image Credit: Forschungsgruppe Alternative Raumfahrtkonzepte |

Below left is the business end of the LEM Descent engine, showing the Pintle Injector:

Below right is an image by Warren W. Thompson at the unveiling of Space-X’s Falcon 1 at the Air & Space Museum on 4 December 2003.

Lunar Module Descent Engine Image Credit: jurvetson on Flickr |

Merlin Engine with Pintle Injector Image Credit: Warren W. Thompson |

| Finally, while explaining the Pintle Injector to a friend, I realized that almost everybody who has a garden or tends a lawn has personal experience with pintles. You all use a nozzle on the end of your watering hose. Crank it down and you get a steady, narrow stream of water shooting out in a long arc. Crank it back the other way when you want to shut it off, and you get a wide, cone shaped fan spray. Now, turn off the water and look at the business end of the garden hose nozzle (please shut the water off first). There in the middle is a round pintle that moves back and forth as you crank the outer casing one way or the other. And the fan shaped spray of water with which you are familiar is what the fuel and oxidizer spray looks like inside the rocket engine. So take another look at the two images above and imagine the fan shaped spray. The only difference is that your spray of water doesn’t explosively combust and throw a rocket into space. |

5 thoughts on “Pintle Injector Rocket Engines”

There’s a great TRW paper about pintle injectors at the following URL:

http://smartdata.usbid.com/datasheets/usbid/2001/2001-q1/pintleenginepaperaiaafinal.pdf

TRW Pintle Engine Heritage and Performance Characteristics

It includes some great pictures of water flowing through the injector (outer flow only, innerflow only, combined flow), illustrating the principle very nicely.

When I looked at the description of the pintle injector, I saw a thing so simple and effective I had to think a little for it to sink in. I fetched a copy of the TRW paper, very interesting reading. This shows large powerful machines can be simple, the developmental end point you are always trying for. Too bad we can’t do a spacesuit like that — or can we, somehow?

How is the noise spectrum from these pintle engines different from that of earlier varieties? I’ve an intuitive feeling the sound is very different, markedly lower amplitude in the higher frequencies. And I’d look for the pintle engine to be less vulnerable to longitudinal ship oscillation.

Titeotwawki — Martha Adams [2010 Sep 05]

Hi,

Pintle injector’s biggest advantage is combustion stability with throttleability. Not onl that the simplicity of its design make it unique amoung other rocket engine injectors. I have made few pintle injectors as part of my project.

You can view few images of pintle injector at this blog http://www.pintleinjector.blogspot.com. If anyone have any new information about pintle injector, it will be very nice to hear.

The actual problem with pintle injectors occurs when they are used with high-boiling-point fuels, such as RP-1. The key to high efficiency with these fuels is to use high-energy atomization of the fuel (small fuel droplets = good mixing and combustion; which is why all diesel engines use fuel injectors). Pintle’s aren’t able to do this anywhere near as well as, say, flat-face rocket engine injectors or high pressure swirl injectors. That’s basically why they’re so reliable. if you want the ultimate in cheap reliability – make your rocket engine low efficiency. Incidentally, that’s also why the Falcon9 is so much bigger than the Atlas5 – it has to store a LOT more fuel than the more-efficient Atlas/RD-180.

This article has a fundamental flaw, the NK-33/43 and its predecessor engines (NK-15/NK-15V) do NOT have pintle injectors. All these engines use gas/liquid swirl co-axial injectors. There are some similarities between the NK-33 injectors and the RD-170/180/191 injectors but there are some differences but there are of the same general design approach. I worked with a number of FSU design bureaus in the past and I do not know of any Soviet designs that ever used a pintle design. They might have tried them on an experimental basis but none that ever went into production