Microgravity construction methods developed to fabricate structures that are too large to be launched intact from Earth.

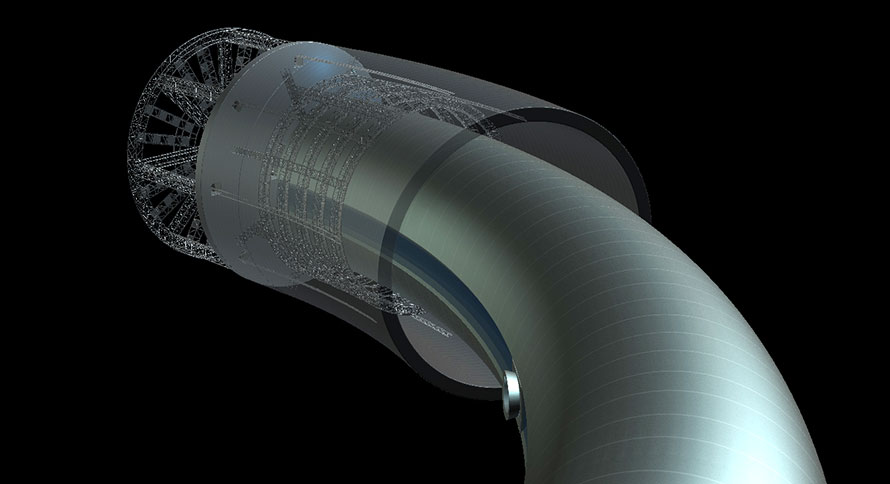

Jig factory fabricating the curving habitation tube for a Stanford Torus setlement. Image: [email protected]

Jig factory fabricating the curving habitation tube for a Stanford Torus setlement. Image: [email protected]

DESCRIPTION

This milestone covers large space structures that are not assembled like the International Space Station, but fabricated into a single piece in space. An example of a fabrication method would be friction-stir welding. Large structures assembled from smaller components have already been built, as has been done with the space station, but the maximum size of these components limits what can be done.

Launchable pre-assembled structure diameters are limited to the diameter of the launch vehicle or those with a wider payload fairing. A larger inflatable structure could be launched if it fits the payload fairing when uninflated.

For example, a typical Stanford Torus (a large habitable space structure) could have a minor diameter of 200 meters and a major diameter of 2000 meters. This would obviously be far too large to be launched from the ground. The large in-space structure fabrication and construction ability can also be applied to fabricating the unpressurized parts of such structures, and very large unpressurized space structures such as jig factories. This capability will enable the construction of rotating space settlements, and the eventual construction of massive starships.

COMPONENTS (requirements)

- Very large robotic jig factories and/or additive manufacturing factories, etc. in orbit. A jig factory is a very large industrial jig (a framework that keeps a workpiece from moving while it is being worked on), where the entire factory is the jig.

- A large supply of construction parts made from material from asteroids or moons.

BARRIERS

- Lack of methods to mine asteroids or moons and to turn the derived materials and minerals into structural components.

- Lack of efficient in-space transport to move heavy materials to the desired sites in space.

- Lack of advanced robotic factory designs, construction methods and robotic software and equipment.

- The difficulty of operating in a vacuum, in microgravity, with a minimum of personnel.

COMPLETION

This milestone can be considered achieved when the first space manufacturing facility is built that can create one-piece structures that are too large to be launched from Earth.

MORE OF THE NSS ROADMAP TO SPACE SETTLEMENT: