The Space Shuttle Decision:

Chapter 5: Shuttle to the Forefront Chapter 5: Shuttle to the Forefront

Chapter 5: Shuttle to the Forefront

Introduction

“I wouldn’t want to be quoted on this,” President Johnson told a gathering in 1967.

We’ve spent $35 or $40 billion on the space program. And if nothing else had come out of it except the knowledge that we gained from space photography, it would be worth ten times what the whole program has cost. Because tonight we know how many missiles the enemy has and, it turned out, our guesses were way off. We were doing things we didn’t need to do. We were building things we didn’t need to build. We were harboring fears we didn’t need to harbor. [Richelson, Secret Eyes, p. 93.]

Within NASA, Apollo addressed the concern that Moscow’s highly-publicized space spectaculars pointed to communism as the way of the future. The Air Force had a separate space program that dealt with the reality of power. Working closely with the CIA, the Air Force had the task of launching reconnaissance satellites that could determine the Soviet order of battle, counting that nation’s bombers and missiles while determining the location of their bases and their operational readiness. In turn, these satellites provided strategic intelligence that shaped America’s Cold War policies.

The Air Force in Space

The background to the Air Force program dated to 1953, shortly after the inauguration of President Eisenhower. In August of that year, the Soviets detonated a nuclear weapon with a yield of 400 kilotons. By studying its fallout, American analysts determined that it was not a true hydrogen bomb. It, however, did represent a large step upward in Soviet nuclear power. In addition to this, the CIA learned that the Soviets were building a turboprop bomber, the Tu-95, with enough range to strike the United States. An intelligence estimate, issued early in 1954, predicted that Moscow would have 500 such bombers in 1957. [Rhodes, Dark Sun, pp. 523-525; Zaloga, Target, pp. 85-88.]

In March 1954, Eisenhower met with a group of advisors and warned them that he feared a surprise attack, a new Pearl Harbor that would destroy cities rather than battleships. Lee DuBridge, the president of Caltech and chair of this advisory group, he responded by taking steps to set up a high-level commission, the Technological Capabilities Panel. It would recommend new policies that could meet this danger. To chair it, Ike recruited James Killian, the president of MIT.

A subpanel, Project 3, dealt with the technical means for surveillance. The people who learned of it included Clarence “Kelly” Johnson of Lockheed, one of the country’s top aircraft designers. He had already prepared a design for a reconnaissance aircraft and, without success, had tried to win support from the Air Force. Johnson now joined with Trevor Gardner, a special assistant to the Air Force secretary, and approached Project 3 for a new try. The subpanel’s chairman, Edwin Land, had invented the Polaroid camera and was president of the Polaroid Corporation. He and Killian took the proposal to Ike and convinced him to accept it. The plane that resulted was the U-2. [McDougall, Heavens, pp. 115-117; Burroughs, Deep Black, pp. 69-75; Killian, Sputnik, pp. 67-71.]

In mid-February 1955, the full Killian Committee issued its report, titled “Meeting the Threat of Surprise Attack.” It declared, “We have an offensive advantage but are vulnerable to surprise attack” (emphasis in original). “Because of our vulnerability, the Soviets might be tempted to try an attack.” In Edwin Land’s section of the report, he wrote,

We must find ways to increase the number of hard facts upon which our intelligence estimates are based, to provide better strategic warning, to minimize surprise in the kind of attack, and to reduce the danger of gross overestimation or gross underestimation of the threat. [Killian, Sputnik, pp. 70, 71, 72, 79, 302.]

At the time, the available “hard facts” were often meager. The 1953 Soviet nuclear test had caught everyone by surprise. Then, on May Day of 1954, at a public air show, the Soviets showed off a new jet bomber, the Bison. Here was another surprise—a Soviet jet bomber. It was all the more worrisome because no one in the U.S. had known of it until the Kremlin displayed it openly. A year later, in preparations for the next such air show, American observers saw a formation of 10 of these aircraft in flight. In mid-July came the real surprise. On Aviation Day, Colonel Charles Taylor, the U.S. air attaché in Moscow, counted no fewer than 28 Bisons as they flew past a review in two groups. This bomber now was obviously in mass production. The CIA promptly estimated that up to 800 Bisons would be in service by 1960.

In fact, Taylor had seen an elaborate hoax. The initial group of 10 Bisons had been real enough. They then had flown out of sight, joined eight more, and this combined formation had made the second flyby. Still, as classified estimates leaked to the press, Senator Stuart Symington, a former Air Force Secretary, demanded hearings and warned the nation of a “bomber gap.” The flap forced Ike to build more B-52 bombers than he had planned, and to step up production of fighter aircraft in the bargain. Yet even when analysts discovered the Aviation Day hoax, they took little comfort. If Moscow was trying to fool the CIA, it might mean that the Soviets were putting their real effort into missiles rather than bombers. [Zaloga, Target, pp. 81-85; Burroughs, Deep Black, pp. 67-68; Prados, Soviet, pp. 41-50; Klass, Sentries, pp. 6-9.]

The U-2 became operational in mid-1956, and proceeded to deliver photos of the highest value. One mission returned with pictures that showed far fewer heavy bombers than expected at Soviet bases. This started a process of downward revision of Moscow’s estimated air power. One of Ike’s military aides declared that “very quickly we found the Bomber Gap had a tendency to recede. It was something that each year was going to occur. But in fact it did not occur.” The U-2 also looked at targets of opportunity, and Richard Bissell, the project manager within the CIA, would recall an example: “He was flying over Turkestan, and off in the distance he saw something that looked quite interesting and that turned out to be the Tyuratam launch site. He came back with the most beautiful photos of this place.” It was one of the principal bases for missile and space launches; yet the CIA had not known of its existence. [Prados, Soviet, pp. 46, 47; Ranelagh, Agency, pp. 316-317.]

Nevertheless, the U-2 delivered far less than it had promised. When it entered service, Soviet radar promptly picked it up. Following the second overflight, the Foreign Ministry lodged a protest. The protests escalated, and after only six such missions, all during July 1956, Ike ordered a standdown. Subsequent flights required his personal approval; over the next four years, only about 15 took place. Then, in May 1960, a Soviet antiaircraft missile downed a U-2 near the city of Sverdlovsk. With this, the overflights ceased completely. [Richelson, Espionage, pp. 142-152; Ruffner, ed., Corona, p. 3; Prados, Soviet, pp. 33-35; Powers, Secrets, pp. 95-97.]

By then a new concern had arisen: the missile gap. Early in 1960, a debate developed in Washington in response to a new intelligence estimate, which predicted that Moscow would possess up to 450 ICBMs in mid-1963. This would be twice America’s anticipated strength in missiles. This was frightening enough; deeper skepticism was raised by the fact that the estimate actually represented a substantial reduction from earlier ones. Senators Symington and Johnson asked whether Ike perhaps was cooking the books, downgrading the perceived threat during an election year. Clearly the nation needed additional strategic reconnaissance, and needed it quickly.

By then, the CIA’s Bissell had been working for nearly two years to address this problem. Early in 1958, he had initiated a highly classified program, Corona, that sought to build reconnaissance satellites known as Discoverer. These were to fly to orbit atop Thor-Agena rockets. It took a year and a half, however, to get the system to work successfully. The first attempt, Discoverer 1, did not even reach orbit. Following launch from Vandenberg Air Force Base in February 1959, it wound up near the South Pole. Finally, in August 1960, Discoverer 13 proved the lucky 13 in the series. Though it carried no photo equipment, it successfully demonstrated the release of a capsule from orbit and its recovery in the Pacific. This was the first spacecraft to reenter from orbit and be retrieved following descent by parachute.

With this encouragement, Bissell allowed Discoverer 14 to fly with its camera. Its capsule, too, was recovered successfully, this time in midair, on August 19. The film soon arrived at the CIA’s Photographic Interpretation Center, and the photo interpreters gathered in an auditorium. The director, Arthur Lundahl, spoke to them about “something new and great we’ve got here.” His deputy then presented a map of the Soviet Union. These maps had previously featured a single narrow line to indicate the coverage along the path of a U-2. This one had eight broad swaths running north to south across the USSR and Eastern Europe, covering over one-fifth of their total area. They represented the regions that this single mission had photographed, and people broke out in cheers. Some photos were fogged by electrostatic discharges, but the resolution was 20 to 30 feet, which analysts described as “good to very good.” Clearly, this was a turning point. [Prados, Soviet, pp. 82-83, 86-95; McDougall, Heavens, pp. 219-220; Time, February 8, 1960, pp. 16-19; Ruffner, ed., Corona, pp. 3-24, 119-120; Richelson, Secret Eyes, pp. 41-44.]

During the election campaign that autumn, Kennedy stressed the issue of the missile gap, warning that the Republicans had done too little to counter its threat. After the election, he appointed a deputy defense secretary, Roswell Gilpatric, who believed strongly that this gap was real. On taking office in January 1961, Gilpatric and his boss, Defense Secretary Robert McNamara, went to the Air Force intelligence office on the fourth floor of the Pentagon and spent several days personally studying Discoverer photographs.

The Air Force held the view that Moscow was building large numbers of well-camouflaged missile sites. Sites for the presumed disguised installations included a Crimean War memorial and a medieval tower. McNamara and Gilpatric, however, preferred the view of Army intelligence: that the Soviet ICBM, designated R-7, was very large and unwieldy and could move only by rail or military road. Discoverer satellites had taken photos along the Soviet Union’s railroads and principal highways—and had found no missile launchers. In February, at an off-the-record press conference, a newsman asked about the missile gap. McNamara replied that “there were no signs of a Soviet crash effort to build ICBMs.” Reporters raced to their phones, newspapers blossomed with the word that no such gap existed, and Kennedy himself had to step in, declaring that it was too early to draw such conclusions. [Richelson, Secret Eyes, pp. 57-58; Prados, Soviet, pp. 114-115, 119; Time, February 17, 1961, pp. 12-13.]

Then in June and July, Discoverers 25 and 26 flew with nearly complete success. While they were only the third and fourth missions to return photos having intelligence value, together these four flights covered more than half of the regions suitable for ICBM deployment. Within this vast area, photo analysts found no more than two new and previously unsuspected ICBM bases. Three others were photographed a second time. By comparing them with one another, and with a known testing complex at Tyuratam, the analysts came away with a clear understanding of just what an ICBM base would look like. That made it possible to eliminate a number of “suspect” launch sites and to give a clear and definitive estimate of Moscow’s ICBM strength.

This assessment, National Intelligence Estimate 11-8/1-61, titled “Strength and Deployment of Soviet Long Range Ballistic Missile Forces,” came out on September 21. It stated:

We now estimate that the present Soviet ICBM strength is in the range of 10-25 launchers from which missiles can be fired against the US, and that this force level will not increase markedly during the months immediately ahead.

The low present and near-term ICBM force probably results chiefly from a Soviet decision to deploy only a small force of the cumbersome, first generation ICBMs, and to press the development of a smaller, second generation system. On this basis, we estimate that the force level in mid-1963 will approximate 75-125 operational ICBM launchers. [Ruffner, ed., Corona, pp. 26-27, 129-130, 137-140; Richelson, Secret Eyes, p. 56; Richelson, Espionage, p. 180.]

There indeed was a missile gap—but it favored the United States, and by a large margin. In 1961, the U.S. was already deploying substantial numbers of its first-generation Atlas, Titan, Thor, and Jupiter missiles. In addition, the first Polaris submarines were on station at sea. Beginning in October 1962, the nation would also have the Minuteman ICBM, which would reach the field in even larger numbers. [Prados, Soviet, pp. 119-122; Neufeld, Ballistic Missiles, pp. 226, 234-237.]

Yet it was hardly a secret in Moscow that the Soviet R-7 was clumsy and unwieldy; that nation’s planners had known this from the start. Why, then, had they taken the trouble to develop it? An answer was in hand, courtesy of Oleg Penkovskiy, a colonel in the Chief Intelligence Directorate of the Soviet army. He had recently begun working for MI-6, Britain’s intelligence agency, and had gone on to help the CIA as well. In May 1961, he delivered rolls of microfilm that included minutes of Kremlin meetings in which officials decided to use the R-7 for space launches, but not as an ICBM.

At the outset of the R-7 program, during the mid-1950s, Soviet officials had expected to fire it from secret bases. This missile would take up to 20 hours to fuel and prepare for launch, and during that time, it would be highly vulnerable to attack. However, if the U.S. did not know where these bases were located, the R-7 would remain safe. The advent of American strategic reconnaissance upset this plan, by giving America the intelligence needed to strike bases during pre-launch preparations. The head of the Soviet strategic missile force, Marshal Mitrofan Nedelin, accordingly decided to delay the deployment of a large fleet of ICBMs until he could receive a more advanced version that could be fueled and launched on short notice. [Prados, Soviet, p. 116; Richelson, Espionage, pp. 56-65; Zaloga, Target, pp. 51-54.]

The Corona program had sought to use satellites to assess the Soviet threat. It did more; it markedly reduced this threat, at least for a time, by piercing the secrecy that formed a major element of Moscow’s strategic calculations. Then, as the 1960s proceeded, the Air Force and CIA, introducing a number of important advances in the satellites, went on to fly them routinely.

Improved resolution was an early goal. The cameras of 1961 achieved a resolution of 25 feet; better versions, in service a year later, reached 10 feet. A further improvement, which first flew in 1967, returned photos with resolution of six feet. To make the best use of these increasingly sharp images, the 1962 and later Discoverer satellites mounted dual cameras that could photograph a site from different directions. This permitted stereophotography, whereby analysts could study images that appeared three-dimensional. Later versions of this spacecraft also carried more film and stayed up longer. The first Discoverers had mission times of a single day; subsequent models stretched this to three weeks and longer.

The six-foot resolution represented a limit for Discoverer. The Thor-Agena booster, used by the Discovere, had only a modest payload capacity. Beginning in 1963, however, the Air Force employed the Atlas-Agena and then the Titan III, which could launch larger spacecraft with telescopes of greater acuity. These rockets supported a separate program, Gambit, that achieved a resolution of 18 inches. For the closest looks, the Air Force used the closest orbits, with Gambit spacecraft dropping down to perigees as low as 76 miles. [Richelson, Secret Eyes, pp. 353-360; Ruffner, ed., Corona, pp. xiv-xv, 27-37; McDonald, ed., Corona, pp. 301-307; Quest, Summer 1995, pp. 22-33.]

What did Corona and Gambit show? They photographed all Soviet ballistic-missile launch complexes, following existing as well as new missiles through development and deployment. In particular, they found and repeatedly observed a major center at Plesetsk, near the northern city of Arkhangelsk. Plesetsk specialized in launching reconnaissance satellites and other military spacecraft. At its height, it accounted for more than half of all space launches in the entire world, with Tyuratam a distant second, and Cape Canaveral and Vandenberg Air Force Base far behind.

Corona also was first to see Severodvinsk, the main construction site for ballistic-missile submarines. This made it possible to monitor the launching of new classes of subs, and to follow them through to operational deployment. The CIA also observed the rapid growth of the Soviet surface navy. Coverage of aircraft plants and air bases kept analysts up-to-date on bombers and fighters, while other coverage allowed Army experts to learn the nature of the tank forces that NATO would face if the Soviets were to invade Europe.

Corona photography uncovered the construction of antiballistic-missile sites near Moscow and Leningrad, along with the radar installations that supported them. Other photos located antiaircraft batteries and made it possible for the Strategic Air Command to find routes for its bombers that could avoid these missiles. Specialized satellites, conducting geodetic mapping, became the main source of data for the military charts of the Defense Mapping Agency.

As recently as the mid-1950s, the Soviets had been able to fool the Americans concerning their air strength, and to touch off a major Washington flap over a supposed “bomber gap,” merely by flying the same aircraft around twice at an air show. By contrast, a 1968 intelligence report contained the unequivocal statement: “No new ICBM complexes have been established in the USSR during the past year.” As early as June 1964, Corona had photographed all 25 of the complexes then in existence. If there had been any new ones, the CIA would have seen them. [Ruffner, ed., Corona, pp. xiv, 37.]

The Air Force and NASA

In 1494, the Treaty of Tordesillas divided up the New World by drawing a line down the Atlantic, with Spain claiming lands to the west of this line and Portugal claiming lands to the east [Durant, Reformation, p. 264]. The activities of NASA and the Air Force lent themselves to similar demarcation. With NASA emphasizing Apollo while the Air Force dealt largely with satellite reconnaissance in low orbit, there was little overlap between their concerns. However, these two agencies did not run independent programs; there was a great deal of cooperation.

This cooperation was particularly strong in the realm of launch vehicles. In launching automated spacecraft, the most important such vehicles were derived from the Thor, Atlas, and Titan ballistic missiles; both NASA and the Air Force used these rockets repeatedly, and procured them from the same contractors. They also shared in ongoing developments that increased their payload capacities.

As early as February 1961, an agreement between NASA’s James Webb and the Pentagon’s Roswell Gilpatric stipulated that neither agency would initiate the development of a new launch vehicle without first seeking the consent of the other. Then in 1962, a joint NASA-DoD Large Launch Vehicle Planning Group issued a report that contained a recommendation: “The 120-inch diameter solid motor and the Titan III launch vehicle should be developed by the Department of Defense to meet DOD and NASA needs, as appropriate in the payload range of 5000 to 30,000 pounds, low earth orbit equivalent.” [NASA SP-4102, p. 218; NASA SP-4407, Vol. II, pp. 318, 323.]

The Titan III brought the prospect of wasteful duplication, for it competed directly with NASA’s Saturn I-B. This Saturn carried over 36,000 pounds to low orbit. The Titan III-C, the first operational version, had a rated payload of 23,000 pounds; its immediate successor, the Titan III-D, raised this to 30,000. In addition to this, the projected Titan III-M promised to carry as much as 38,000. Nevertheless, as early as 1967, the President’s Science Advisory Committee noted that “the launch costs of the [Saturn I-B] are about double those of the Titan III-M.” [NASA SP-4012, Vol. III, pp. 27, 39; Thompson, ed., Space Log, Vol. 27 (1991), p. 125; Quest, Fall 1995, p. 18; Long, chairman, Space Program, p. 36.]

Because NASA was accustomed to receiving launch vehicles that the Air Force had developed, it yielded gracefully when the Saturn I-B came under pressure. NASA had conducted the initial flight test of a Saturn-class first stage as early as October 1961, at a time when the Titan III was still at the level of preliminary study. In view of this early start, and because the Saturn I-B was essential for Apollo, NASA went on to build 14 of them, though George Mueller hoped for more as he pursued Apollo Applications. When budget cuts hit home, however, NASA abandoned the Saturn I-B and turned to the Titan III-E Centaur. It had the energy to launch large payloads on missions to Mars and the outer planets, and did so repeatedly. [NASA SP-4012, Vol. II, pp. 54-57; Vol. III, pp. 40-41; Aviation Week, August 3, 1970, p. 45.]

Titan III, left, which replaced the more costly Saturn I-B. The two launch vehicles carried nearly the same payload. Human figure at bottom indicates scale. (Art by Dan Gauthier)

In addition to launch vehicles, NASA turned to the Air Force for facilities used for launch and tracking. When NASA’s rockets flew from Cape Canaveral, they proceeded down the Eastern Test Range—which the Air Force operated. That service provided tracking stations, and when NASA built stations of its own on the islands of Antigua and Ascension, they were co-located near those of the Defense Department.

Cape Canaveral in 1972. The space shuttle was to use the Apollo facilities, including the VAB and LC-39. (NASA)

The Air Force also built up an extensive array of launch facilities at Cape Canaveral. When NASA took over nearly exclusive use of some of them, the Air Force transferred them to NASA outright. These included Launch Complex 12 for Atlas-Agena, LC 36 for Atlas-Centaur, and LC 19 for the Titan II. Other launch pads served both agencies: LC 17 for Delta, LC 41 for Titan III. In addition to this, NASA launched early versions of Saturn, including the Saturn I-B, from LC 34 and 37, which had been built on land owned by the Air Force.

The two agencies also cooperated closely in research. The Air Force had a valuable set of wind tunnels and engine-test facilities at its Arnold Engineering Development Center in Tennessee. This service, however, did not attempt to duplicate the far more extensive facilities of NASA-Ames, Langley, and Lewis. In addition to a broad array of supersonic wind tunnels, NASA offered such unique installations as a wind tunnel at Ames Research Center with a 40 by 80-foot cross section, big enough to hold and test full-size fighter aircraft. At NASA-Langley, a 60-foot vacuum sphere could accommodate large spacecraft and rocket stages. [NASA SP-4102, pp. 213, 221, 229, 236; NASA SP-440.]

In addition to sharing facilities, NASA and the Air Force also pursued joint ventures in research. The X-15 was one; another, the XB-70, involved large aircraft that could fly at Mach 3. The agencies also collaborated in building immense solid-propellant rockets. At Edwards Air Force Base, NASA built test stands for rocket engines used in Apollo. These complemented earlier Air Force test facilities.

Institutional arrangements also bound them closely. Between 1958 and 1964, NASA and the Defense Department executed some 88 major agreements. A joint Aeronautics and Astronautics Coordinating Board (AACB) dealt with such areas as aeronautical research, launch vehicles, spacecraft, and piloted space flight. NASA’s Deputy Administrator and the DoD’s Director of Defense Research and Engineering co-chaired this board; as early as 1966, an AACB subpanel carried out an important review of concepts for reusable launch vehicles.

Within the Defense Department, the Air Force Systems Command (AFSC) held overall responsibility for that service’s space and missile programs. In downtown Washington, an AFSC liaison office shared a building with NASA’s Office of Manned Space Flight (OMSF). After 1962, NASA had its own Office of Defense Affairs that performed a similar function. [NASA SP-4102, pp. 213, 217-220, 294 (footnote 17); Ames, chairman, Report.]

Yet, this interagency cooperation would only go so far. In August 1963, Webb and McNamara signed an agreement that sought “to ensure that in the national interest complete coordination is achieved” in pursuing a joint space-station project. Only a month later, McNamara sent Webb a follow-up letter that expressed his reservations. Then in December, McNamara made it clear that at least for the short term, the Air Force would want a piloted orbital facility of its own. [NASA SP-4407, Vol. II, pp. 356-360.]

When he canceled Dyna-Soar, on December 10, he handed the Air Force a consolation prize by inviting that service to conduct studies of a new project, the Manned Orbiting Laboratory (MOL). MOL took shape as a cylinder, 10 feet across by 41 feet long, with a Gemini spacecraft at one end; this ensemble was to ride to orbit atop a Titan III. McNamara could not grant formal approval for MOL; that had to come from the White House, and this raised anew the question of what the Air Force might do with such a facility. While that service had failed to provide good justification for Dyna-Soar, this time it came up with a fine reason for MOL: strategic reconnaissance.

The eventual plan called for MOL to carry a telescope with aperture of six feet, offering resolution of nine inches. Astronauts would avoid photographing cloud-covered regions, but would scan the ground with binoculars, looking for items of interest. The Air Force won support from such key figures as Kermit Gordon, director of the Budget Bureau, and Donald Hornig, the White House science advisor. In August 1965, President Johnson gave MOL his endorsement, which meant it could go forward to contract award and development.

By then George Mueller was nurturing hopes for Apollo Applications, which raised anew the prospect of duplication. NASA officials, unwilling to affront the Air Force, supported MOL and took the view that it was not the national space station contemplated in the 1963 Webb-McNamara agreement. Nevertheless, members of Congress as well as Budget Bureau officials soon were asking whether NASA could adopt a version of MOL for its own use. [NASA SP-4102, pp. 230-235; Richelson, Secret Eyes, pp. 82-83, 90-91; NASA SP-4208, pp. 17-19.]

In January 1966, Senator Clinton Anderson, chairman of the Senate space committee, sent a letter to Webb that recommended use of MOL. Within the House, the Military Operations Subcommittee criticized Mueller’s plan for “unwarranted duplication” and called for MOL to proceed as a joint NASA-Air Force program—with the Air Force in charge. Budget Bureau officials also supported a common program. In February 1967, the President’s Science Advisory Committee added its own views, calling for “maximum utilization” of MOL and calling on NASA to carefully consider its use “before substantial funds are committed” to Apollo Applications.

NASA responded by having Douglas Aircraft, the MOL prime contractor, evaluate the suitability of MOL for NASA’s objectives. The agency also conducted in-house studies. These began by acknowledging that the Saturn I-B was far more costly than the Titan III, and considered whether it might be advantageous to have the latter launch Apollo spacecraft. The OMSF concluded that while this was possible, it would cost $250 million to develop such a Titan-Apollo, which would then require 17 launches before the savings surpassed the initial cost of conversion.

The OMSF also concluded that MOL was too small for NASA’s needs. It was no larger than a house trailer, whereas Mueller had described his proposed wet workshop as being the size of “a small ranch house.” While the Air Force had a proposal in hand for a larger MOL, this would cost an additional $480 million and would take four years to develop. In comparison, even the Saturn I-B would cost less to use. These arguments mollified the critics, and Apollo Applications went forward, though with a reduced budget. [NASA SP-4208, pp. 43, 46-48, 54; NASA SP-4102, p. 232; Long, chairman, Space Program, pp. 23-25.]

MOL also went forward, with strong Pentagon support. The Air Force, however, never having carried through the development of a piloted spacecraft, failed to control its cost. Between 1965 and 1969, the projected cost of MOL ballooned from $1.5 billion to $3 billion. During those same years, the escalating Vietnam War placed military programs under severe strain.

The future of MOL came up for discussion at a White House meeting between Nixon, national security advisor Henry Kissinger, and Budget Bureau director Robert Mayo. Though the program carried the strong endorsement of Defense Secretary Melvin Laird and the Joint Chiefs of Staff, it proved to lack support from a key official: Richard Helms, Director of Central Intelligence and head of the CIA. In the words of the analyst Jeffrey Richelson, Helms’s advisers “feared that an accident that cost the life of a single astronaut might ground the program for an extended period of time and cripple the reconnaissance program.”

Mayo suggested canceling MOL; Nixon and Kissinger agreed. Only then did Mayo discuss the matter with Laird, who had not even believed that MOL was in trouble. Though Laird appealed directly to Nixon, emphasizing that the Joint Chiefs firmly supported this program, Nixon turned him down. The public announcement of the end of MOL came on June 10, 1969, with its first piloted flight still three years in the future. [Richelson, Secret Eyes, pp. 101-103.]

During the 1960s, the Air Force pursued two major and separate efforts—Dyna-Soar and MOL—that sought to place military astronauts in orbit. This service ended the decade with both projects canceled and with nothing to show for its efforts. Clearly, if it was to send such astronauts aloft, it would not do so on its own, but would have to work in cooperation with NASA.

In addition to this, the experiences of the Titan III, the Saturn I-B, MOL, and Apollo Applications, had shown clearly that these agencies could easily introduce wasteful duplication by pursuing their own programs. This made it plausible that a cooperative NASA-Air Force program, focusing on piloted flight to orbit, would take shape as a national program, a unified effort shaped to serve the needs of both agencies.

Clearly, Air Force involvement would emphasize strategic reconnaissance, which represented the main rationale for that service’s activities in space. The experience of MOL, however, showed that it would not do simply to propose that astronauts could operate telescopes and cameras from orbit. Instead, the Air Force would have to use piloted flight to support its work with automated reconnaissance satellites, such as those of Corona and Gambit.

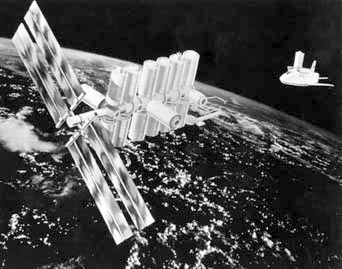

As early as 1963, NASA and the Air Force had executed the Webb-McNamara agreement, which contemplated a joint space station. With MOL now canceled, it was difficult to see how the Pentagon could justify major participation in the space station that NASA’s Tom Paine wanted so badly. The Space Shuttle was another matter. By launching, retrieving, and servicing spacecraft, it might significantly enhance the ability of the Air Force to conduct strategic reconnaissance. In turn, by serving Air Force needs, the Shuttle might indeed take shape as a truly national system, carrying military as well as civilian payloads. Beginning in 1969, the evolution of the Space Shuttle oncept took a sharp turn in this direction.

A New Shuttle Configuration

When a new round of shuttle design studies got under way, early in 1969, the field had seen no truly new concept since Max Hunter’s partially-reusable Star Clipper of several years earlier. While work went forward at the contractors, Max Faget, at the Manned Spacecraft Center, carried through a parallel effort of his own that indeed came up with a new approach. His configuration not only went on to dominate the alternatives; it changed the terms of the ongoing discussions. These discussions had emphasized such issues as full versus partial reusability, with neither approach finding expression in a generally-accepted design concept. Faget now introduced a specific concept: a two-stage fully-reusable shuttle. As it gained acceptance, it spurred debate over its specific features, notably size, payload capacity, and choice of wing design. By focusing the debate, Faget’s work thus narrowed the topics that subsequent studies would address, and enabled these studies to achieve greater depth.

Maxime Faget. (NASA)

Faget was an aerodynamicist who had built his career at NACA’s Langley Aeronautical Laboratory. He was a member of the Pilotless Aircraft Research Division, an early nucleus of activity in high speed flight. In 1954, he took part in an initial feasibility study that led to the X-15. He then found a point of departure for his subsequent career in the findings of his fellow NACA aerodynamicists, H. Julian Allen and Alfred Eggers. They had shown that for a reentering nose cone, a blunt shape would provide the best protection against the heat of reentry.

Working with a longtime associate, Caldwell Johnson, Faget proceeded to devise a suitable blunt shape for Project Mercury, which put America’s first astronauts in orbit. His Mercury capsule took shape as a cone, with its broad end forward and covered with a thick layer of material to provide thermal protection. (A cutaway view of this concept, elegantly rendered, hangs in Faget’s offices to this day.) He came to Houston as a founding member of the Manned Spacecraft Center (MSC), where he became Director of Research and Engineering. He also adapted his basic shape to provide capsules for Gemini and Apollo. [Author interview, Max Faget, Houston, March 4, 1997; AAS History Series, Vol. 8, p. 299; NASA SP-4307 and NASA SP-4308, index references under “Faget.”]

“My history has always been to take the most conservative approach,” he declares. In this frame of mind, he disliked much of the work done to date on Space Shuttle concepts. Lifting-body configurations were popular; Lockheed’s Max Hunter had used them in his Star Clipper. Faget acknowledged their merits: “You avoid wing-body interference,” which brings problems of aerodynamics. “You have a simple structure. And you avoid the weight of wings.” He saw difficulties, however, that were so great as to rule out lifting bodies for a practical shuttle design.

They had low lift and high drag, which meant a dangerously high landing speed. As he put it, “I don’t think it’s charming to come in at 250 knots.” Engineers at McDonnell Douglas, studying their Tip Tank lifting body, had tried to improve the landing characteristics by adding small wings that would extend from the body during the final approach. This appeared as very makeshift.

Because they required a fuselage that would do the work of a wing, lifting bodies also promised serious difficulties in development. It would not be possible to solve aerodynamic problems in straightforward ways; the attempted solutions would ramify throughout the entire design. In his words, “They’re very difficult to develop, because when you try to solve one more problem, you’re creating another problem somewhere else.” His colleague Milton Silveira, who went on to head the MSC Shuttle Engineering Office, held a similar view:

If we had a problem with the aerodynamics on the vehicle, where the body was so tightly coupled to the aerodynamics, you couldn’t simply go out and change the wing. You had to change the whole damn vehicle, so if you made a mistake, being able to correct it was a very difficult thing to do. [Author interview, Max Faget, Houston, March 4, 1997; Joe Guilmartin and John Mauer interview, Milton Silveira, Washington, November 14, 1984, p. 14.]

Instead, Faget proposed to build each of his shuttle’s two stages as a winged airplane, with thermal protection on the underside. Before it could fly as an airplane, such a shuttle would first have to reenter, which meant it would need the high drag of a blunt body. “With extremely high drag,” he notes, “you throw a big shock wave in front of you, and all the energy goes into that shock.” Even with thermal protection, he did not want to fly his shuttle during reentry, in the manner of an airplane: “It’s a hell of a lot easier to do a no-lift entry than a lifting entry, from the standpoint of heat protection.” With airplane-style reentry, “you are stuck in the atmosphere, going fast for a long time.” Rather than lose energy to a shock wave, the airplane would experience drag through friction with the atmosphere which would transfer heat to its surface.

Faget’s shuttle concept. (NASA)

Faget expected to turn his airplane into a blunt body by the simple method of having it reenter at a very high angle of attack, with its broad lower surface facing the direction of flight. In effect, he would take an Apollo capsule, with its large circular heat shield, and trim it to the shape of an airplane with wings. This concept drew on the experience of the X-15 that looked like a fighter plane but reduced its reentry heating by coming in nose-high. It also revived a design approach introduced a decade earlier by NASA’s Charles Mathews. He had also proposed to build a winged spacecraft as a glider that would reenter with its bottom side facing forward.

Faget wrote that “the vehicle would remain in this flight attitude throughout the entire descent to approximately 40,000 feet, where the velocity will have dropped to less than 300 feet per second. At this point, the nose gets pushed down, and the vehicle dives until it reaches adequate velocity for level flight.” This dive would cost some 15,000 feet of altitude. The craft then would approach a runway and land at a moderate 130 knots, half the landing speed of a lifting body.

Faget wrote that because its only real flying would take place during this landing approach, a wing design “can be selected solely on the basis of optimization for subsonic cruise and landing.” The wing best suited to this limited purpose would be straight and unswept, like the wings of fighter planes in World War II. A tail would provide directional stability, again as with a conventional airplane. By moving control surfaces on the horizontal stabilizer, a pilot then could raise the nose slightly just before touching down on a runway, in a maneuver called a flare which adds lift and makes the touchdown gentle. [Astronautics & Aeronautics, January 1970, pp. 52-61; author interview, Max Faget, Houston, March 4, 1997; Faget and Silveira, Fundamental Design Considerations, October 1970.]

Faget’s concept had the beauty of simplicity, and, inevitably, knowledgeable specialists would criticize it as being too simple. The Air Force Flight Dynamics Laboratory (FDL), at Wright-Patterson Air Force Base, quickly emerged as a center of such criticism. The FDL had sponsored space shuttle studies in parallel with those of NASA, and had investigated such concepts as Lockheed’s Star Clipper. One of its managers, Charles Cosenza, had been a leader in the development of ASSET. Another FDL scientist, Alfred Draper, was a leader in the field of space systems. Beginning in early 1969, he took the initiative in questioning Faget’s approach. [Jenkins, Space Shuttle, pp. 36, 56; Hallion, ed., Hypersonics, p. 459; Astronautics & Aeronautics, January 1971, p. 28.]

Draper did not accept the idea of building a shuttle as an airplane that would come in nose-high, then dive through 15,000 feet to pick up flying speed. With its nose so high, the plane would be fully stalled, and the Air Force disliked both stalls and dives, regarding them as preludes to an out-of-control crash. Draper preferred to have the Shuttle enter its glide while still supersonic, thus maintaining much better control while continuing to avoid aerodynamic heating.

If the Shuttle was to glide across a broad Mach range, from supersonic to subsonic, then it would encounter an important aerodynamic problem: a shift in the wing’s center of lift. Although a wing generates lift across its entire lower surface, one may regard this lift as concentrated at a point, the center of lift. At supersonic speeds, this center is located midway down the wing’s chord (the distance from leading to trailing edge). At subsonic speeds, this center shifts and moves forward, much closer to the leading edge. Keeping an airplane in proper balance requires the application of an aerodynamic force that can compensate for this shift.

The Air Force had extensive experience with supersonic fighters and bombers that had successfully addressed this problem, maintaining good control and handling characteristics from Mach 3 to touchdown. Particularly for large aircraft—the B-58 and XB-70 bombers, and the SR-71—the preferred solution was a delta wing, triangular in shape. Typically, delta wings ran along much of the length of the fuselage, extending nearly to the tail. Such aircraft dispensed with horizontal stabilizers and relied instead on elevons, control surfaces resembling ailerons set at the wing’s trailing edge. Small deflections of these elevons then compensated for the shift in the center of lift, maintaining proper trim and balance without imposing excessive drag. [Hallion, Hypersonic, p. 1032; author interview, Dale Myers, Leucadia, California, December 6, 1996.]

Straight-wing orbiter, top, and delta-wing orbiter. (Art by Dennis Jenkins)

Draper proposed that both stages of Faget’s shuttle should feature delta wings, rather than straight ones. Faget would have none of this. Though he acknowledged the center-of-lift problem, he expected to avoid it: “The straight wing never flew at those speeds; it fell at those speeds.” A delta wing with elevons promised problems at landing, when executing the flare prior to touchdown. That flare was to add lift, but raising the elevons would increase the drag-with the added lift coming only after the nose had time to come up. This momentary rise in drag would make the landing tricky and possibly dangerous.

To achieve a suitably slow landing speed, Faget argued that the delta wing would need a large wingspan. A straight wing, having narrow chord, would be light and would offer relatively little area demanding thermal protection. A delta of the same span, necessary for a moderate landing speed, would be physically much larger than the straight wing. It would add considerable weight, and would greatly increase the area that would receive thermal protection.

Draper responded with his own viewpoint. For a straight wing to deal with the shift in center of lift, a good engineering solution would call for installation of canards, small wings mounted well forward on the fuselage that would deflect to give the desired control. Canards produce lift, and would tend to push the main wings farther to the back. These wings would be well aft from the beginning, for they would support an airplane that was empty of fuel but that had heavy rocket engines at the tail, placing the airplane’s center of gravity far to the rear. The wings’ center of lift was to coincide closely with this center of gravity. Draper wrote that the addition of canards “will move the wings aft and tend to close the gap between the tail and the wing.” The wing shape that fills this gap is the delta; Draper added that “the swept delta would most likely evolve.”

The delta also had other advantages as well. Being thick where it joins the fuselage, it would readily offer room for landing gear. Its sharply-swept leading edge meant that a delta would produce less drag than a straight wing near Mach 1. In addition to this, when decelerating through the sound barrier, a delta would shift its center of lift more slowly. The combination of a sudden drag rise near Mach 1, combined with a rapid center-of-lift shift, would produce a sudden and potentially disconcerting change in the stability characteristics of a straight-winged shuttle when slowing through the speed of sound. This change in stability would be much less pronounced with a delta, and would give a pilot more time to react. [Author interview, Max Faget, Houston, March 4, 1997; Astronautics & Aeronautics, January 1970, pp. 26-35; AIAA Paper 70-1249.]

The merits of deltas might have remained a matter for specialists for another important feature of the delta: Compared to the straight wing, it produced considerably more lift at hypersonic speeds. Using this lift, a reentering shuttle could achieve a substantial amount of crossrange, flying large distances to the left or right of an initial direction of flight. The Air Force wanted plenty of crossrange, and the reasons involved its activity in strategic reconnaissance. In particular, these reasons drew on recent experience involving the Six-Day War in the Middle East in 1967, and the Soviet invasion of Czechoslovakia in 1968.

The Six-Day War broke out suddenly, pitting Israel against a coalition led by Egypt whose tanks and aircraft came largely from the Soviet Union. Though America’s intelligence community sought to follow the fighting closely, its means proved to be limited. A ship near the Israeli coast, the USS Liberty, monitored the communications of the belligerents—until the Israelis bombed it. Though spy planes, such as the U-2 and SR-71, could look down through clear desert skies, experience had shown that the U-2 was vulnerable to antiaircraft missiles. Satellite reconnaissance relied on Gambit and Corona, which had been designed to follow the slow development and deployment of missiles and other strategic weapons. They were not well-suited to the swift battle maneuvers of the 1967 war, and Defense Secretary McNamara does not recall that these spacecraft played any role in U.S. intelligence-gathering during those six days. By the time Corona photography became available, the war was over already.

Then, in August 1968, the Soviets stormed into Prague. A Gambit spacecraft, launched on August 6, performed poorly and was deorbited before the invasion took place. In addition to this, the CIA had a Corona satellite that entered orbit on August 7. It carried two capsules for film return. The first one appeared reassuring; it showed no indications of Soviet preparations for an attack. The second capsule returned photos that clearly showed such preparations, including massing of troops. By the time that film reached Washington, however, those photos were of historical interest only. The invasion had already taken place. [Richelson, Secret Eyes, pp. 94-96, 97-99.]

Clearly, the CIA needed real-time space reconnaissance, and its pursuit of this goal would represent one more instance wherein a task originally thought to require astronauts would be accomplished using automated electronics. The true solution would lie in doing away with photographic film, which took time to expose and return. This film would give way to a new electronic microchip called a charge-coupled device. With an image focused onto this chip, it would convert the image into a rapid series of bits. The data, transmitted to the ground, would give the desired real-time photography, and with very high resolution. In addition to this, by freeing reconnaissance satellites from the need to carry and return film, this invention would allow such spacecraft to remain in orbit and to operate for years. [Ibid., pp. 124-132, 362; Quest, Summer 1995, pp. 31-32.]

The charge-coupled device grew out of the work of two specialists at Bell Labs, William Boyle and George Smith. In 1969, such technology still lay in the future. The view in the Air Force was that the CIA would need piloted spacecraft to produce the real-time photos. The late lamented MOL had represented a possible method, for an onboard photointerpreter might take, develop, and analyze photos on short notice. Now, with MOL in its graveyard, attention turned to the Space Shuttle. It might fly into space, execute a single orbit, and return to its base with film exposed less than an hour earlier.

Because much of the Soviet Union lies above the Arctic Circle, the Air Force was accustomed to placing reconnaissance satellites into polar orbits. It could not do this by firing its boosters from Cape Canaveral; geography dictated that these boosters would fly over populated territory. A launch to the north carried the hazard of impact in the Carolinas; a launch to the south would compromise security if the rocket fell on Cuba. Hence, the Air Force maintained its own space center at Vandenberg AFB, on the California coast. It offered a clear shot to the south, across thousands of miles of open ocean. [Time, December 15, 1958, pp. 15, 41-42.]

While a satellite orbit remains fixed in orientation with respect to distant stars, the earth rotates below this orbit. This permitted single reconnaissance missions to photograph much of the Soviet Union. However, it meant that if a shuttle was to execute a one-orbit mission from Vandenberg, it would return to the latitude of that base after 90 minutes in space only to find that, due to the earth’s rotation, this base had moved to the east by 1100 nautical miles. Air Force officials indeed expected to launch the Shuttle from Vandenberg, and they insisted that the Shuttle had to have enough crossrange to cover that distance and return successfully.

The Air Force had other reasons to want once-around missions. Its planners were intrigued by the idea of using the Shuttle to retrieve satellites in orbit. They hoped to snare Soviet spacecraft in such a fashion—and because Moscow might defend such assets by deploying an antisatellite weapon, the Air Force took the view that if the thing was to be done at all, it was best to do it quickly. A once-around mission could snare such a spacecraft and return safely by the time anyone realized it was missing.

In addition to this, NASA and the Air Force shared a concern that a shuttle might have to abort its mission and come down as quickly as possible after launch. This might require “once-around abort,” which again would lead to a flight of a single orbit. A once-around abort on a due-east launch from Cape Canaveral would not be too difficult; the craft might land at any of a number of sites within the United States. In the words of NASA’s Leroy Day, “If you were making a polar-type launch out of Vandenberg, and you had Max’s straight-wing vehicle, there was no place you could go. You’d be in the water when you came back. You’ve got to go crossrange quite a few hundred miles in order to make land.” [Personal discussions with John Pike, Federation of American Scientists, July 1997; John Mauer interview, Leroy Day, October 17, 1983, p. 41; Pace, Engineering, pp. 146-149.]

The Air Force had ample opportunity to emphasize its desire for crossrange by working within the Joint Study Group that Paine and Seamans had set up to seek a mutually-acceptable shuttle design. There were informal discussions as well. George Mueller, who continued to head NASA’s OMSF through the whole of 1969, met repeatedly with Air Force representatives at his home in Georgetown, close to downtown Washington. One of his guests was Michael Yarymovych, an Air Force deputy assistant secretary. Another guest, Grant Hansen, was assistant secretary for research and development. He and Mueller also were co-chairmen of the joint study. [Mueller, Briefing, 5 May 1969, p. 2; Pace, Engineering, p. 103.]

These Air Force leaders knew that they held the upper hand. They were well aware that NASA needed a shuttle program and therefore needed both the Air Force’s payloads and its political support. The payloads represented a tempting prize, for that service was launching over two hundred reconnaissance missions between 1959 and 1970 [Quest, Summer 1995, pp. 22-33; Winter 1995, pp. 40-45]. In addition to this, Air Force support for a shuttle could insulate NASA quite effectively from a charge that the Shuttle was merely a step toward sending astronauts to Mars.

Yet while NASA needed the Air Force, the Air Force did not need NASA. That service was quite content with existing boosters such as the Titan III. “Sure, NASA needs the shuttle for the space station,” Hansen said in the spring of 1970. “But for the next 10 years, expendables can handle the Air Force job. We don’t consider the Shuttle important enough to set money aside for it.”

Yarymovych has a similar recollection:

NASA needed Air Force support, both for payloads and in Congress. I told Mueller we’d support the Shuttle, but only if he gave us the big payload bay and the crossrange capability, so we could return to Vandenberg after a single orbit. Mueller knew that would mean changing Max Faget’s beloved straight-wing design into a delta wing, but he had no choice. He agreed. [Grey, Enterprise, pp. 67-68.]

It was not that simple, of course; no impromptu discussion in Mueller’s home would settle such an issue. Rather, it was a matter for the formal protocols of Air Force-NASA cooperation. There was strong conflict between these agencies’ wishes, for a NASA baseline document of June 1969, “Desired System Characteristics,” emphasized that NASA needed only 250 to 400 n.mi. of crossrange, enough to assure a return to Cape Canaveral at least once every 24 hours. Faget’s straight-wing shuttle could achieve 230 n.mi.; straightforward modifications would meet NASA’s modest requirements.

To give the Air Force its 1100 n.mi. of crossrange would impose a serious penalty in design, by requiring considerably more thermal protection. The change to a delta wing, even without crossrange, would add considerably to the wing area demanding such protection. Crossrange then would increase this requirement even further. The Shuttle would achieve its crossrange by gliding hypersonically, and hence would compromise the simple nose-high mode of reentry that would turn it into a blunt body. This hypersonic glide would produce more lift and less drag. It also would increase both the rate of heating and the duration of heating. Crossrange thus would call for a double dose of additional thermal protection, resulting in a shuttle that would be heavier-and more costly. [Day, manager, Task Group Report, Vol. II, June 12, 1969, pp. 40-42; Astronautics & Aeronautics, January 1970, pp. 57, 59; Faget and Silveira, Fundamental Design Considerations, October 1970, pp. 5, 17.]

Comparison of types of orbiter. The straight-wing design has low lift, L/D = 0.5. It achieves little crossrange, but its re-entry is brief and limits the heating rate. The delta-wing orbiter has high lift, L/D = 1.7, and achieves large crossrange. But its re-entry is prolonged and imposes both a high heating rate and a high total heat. (NASA)

Even in its simple straight-wing form, Faget’s concept of a two-stage fully-reusable shuttle did not take NASA by storm. It won its pre-eminence only after a process of review and evaluation that extended through 1969 and into 1970. The framework for this process involved the contractors’ studies of shuttle configurations that had begun early in 1969. Those studies ruled out expendable boosters for a reusable shuttle, for such boosters were found to exceed the Saturn V in size. Fully- and partially-reusable shuttle concepts remained in the running, and Faget’s concept counted as a new example of the former. NASA proceeded to examine it alongside several alternatives, beginning in mid-1969.

The initial round of studies, during the first half of 1969, had come to $1.2 million, divided equally among four contractors. NASA now extended these studies by giving $150,000 more to each of three contractors, with McDonnell Douglas receiving $225,000. The participating companies also received new instructions that redirected their work.

North American Rockwell had examined expendable boosters. With this approach now out of favor, this firm was free to direct its attention to something new. This proved to be Faget’s straight-wing concept, largely in the form he recommended.

McDonnell Douglas, which had examined its Tip Tank stage-and-a-half design, now switched to two-stage fully-reusables. These, however, were not Faget’s, but rather continued an earlier line of work. They featured orbiter designs derived from the HL-10 lifting body, with this contractor’s engineers considering 13 possible configurations for the complete two-stage vehicle.

At first, the other two contractors saw little change in their assignments. Lockheed was to continue with studies of Star Clipper and of its own version of the Triamese. General Dynamics, home of the initial Triamese concept, was to study variants of this design, and would also apply its background to design a fully-reusable concept having only two elements rather than the three of Triamese.

The orders for this redirection went out on June 20, 1969. Within weeks, the studies brought a flurry of activity that further narrowed the admissible choices. Expendable boosters had already fallen by the wayside. On August 6, a meeting of shuttle managers brought a decision to drop all partially-reusable systems as well. With this, both Lockheed’s Star Clipper and McDonnell Douglas’s Tip Tank were out. This decision meant that NASA would consider only fully-reusable concepts. [Akridge, Space Shuttle, pp. 53, 71-72, 90; Jenkins, Space Shuttle, pp. 60-64.]

Partially-reusable designs had represented an effort to meet economic goals by seeking a shuttle that would cost less to develop than a fully-reusable system, even while imposing higher costs per flight. This approach had held promise prior to the spring of 1969, when the Shuttle had been considered largely as a means of providing space station logistics. Now its intended uses were broadening to include launches of automated spacecraft, which meant it might fly far more often. The low cost per flight of a fully-reusable now made it attractive, and encouraged NASA to accept its higher development cost. [Day, manager, Summary Report, December 10, 1969.]

Fully-reusable shuttle concepts of 1969; R indicates the stage is reusable. 1: Triamese of General Dynamics. 2: Two-stage arrangement with both stages thrusting at launch. 3: Two stages, upper stage ignited at high altitude. 4: Faget’s concept. 5: Concept of NASA-Langley, with both stages as lifting bodies. (NASA)

There were at least five ways to build a fully-reusable shuttle, and NASA had appropriate designations and descriptions:

FR-1: the Triamese;

FR-2: a two-stage vehicle with the engines of both stages ignited at launch;

FR-3: a two-stage vehicle with engines in the orbiter ignited only upon staging (Faget’s shuttle was an FR-3; so were the concepts of McDonnell Douglas);

FR-4: a variant of the Triamese with the core stage not of the same length as the twin booster stages;

FR-5: a concept designed to avoid a shift in its center of gravity as its propellant tanks would empty, thus easing problems of stability and control.

On September 4, another meeting eliminated the Triamese configurations. The initial concept, the FR-1, had called for three elements of common length and structural design. It had proven difficult, however, to have one shape serve both as booster and orbiter; to Silveira, “it gets all screwed up, so you get a lousy orbiter and a lousy booster, but you don’t get one that does well.” Advocates of the Triamese had turned to the FR-4, with its unequal-length design. This, however, proved heavier than the FR-3, while requiring two booster elements rather than one. It also lost much of the potential cost saving from design commonality between the three elements.

The FR-3 and FR-5 remained. The latter had few advocates; the problem of center-of-gravity shift was not so severe as to call for the design innovations of this class of concepts. The manager Max Akridge writes, “It was felt at this time that clearly, the FR-3 configuration was the forerunner.” [Akridge, Space Shuttle, p. 93; Jenkins, Space Shuttle, pp. 66-70; Joe Guilmartin and John Mauer interview, Milton Silveira, Washington, November 14, 1984, pp. 12-13.]

These decisions brought a further redirection in the studies, for while North American Rockwell had gotten an early start on Faget’s concept, the other three contractors had to change course. McDonnell Douglas, having found no advantage in its lifting-body orbiters, turned to winged orbiters resembling those of Faget.

While Lockheed also turned to the FR-3, it did not embrace Faget’s concept wholeheartedly. This company had spent several years studying Star Clipper, which featured a lifting-body orbiter, triangular in shape. This now looked like a good way to meet Air Force crossrange requirements, and Lockheed’s new design retained this lifting body, with a broad underside in the shape of a delta.

General Dynamics showed its own individuality. That firm had designed its Triamese with retractable wings, which would fold into the body during flight but swing outward for landing. This eased the problem of providing these wings with thermal protection, because the fuselage would shield them. This feature now reappeared in the company’s new FR-3. It drew on more than Triamese; it also reflected company experience with swinging wings. These were part of the F-111 fighter-bomber, which swung its wings to achieve good performance in both subsonic and supersonic flight. [Reports MDC E0056 (McDonnell Douglas); GDC-DCB69-046 (General Dynamics); SD 69-573-1 (North American Rockwell); LMSC-A959837 (Lockheed); Jenkins, Space Shuttle, pp. 63-70.]

Hence, by the end of 1969 NASA had settled on the FR-3 as its choice, with Faget’s specific concept in the forefront. This raised important questions concerning thermal protection. The booster was to be as large as a Boeing 747, yet was to outperform the X-15, reaching considerably higher speeds. The orbiter would be longer than a Boeing 707. For both, the thermal protection had to be reusable.

Within the industry, a standard engineering solution called for the use of hot structures. This approach had a background that included the X-15, Dyna-Soar, ASSET, as well as the Lockheed SR-71 that was flying routinely above Mach 3. Hot structures typically called for titanium as the basic material, covered with high temperature insulation and an outer skin formed of metallic shingles. The metal was molybdenum or columbium, to withstand extreme temperatures while radiating away the heat. Like the shingles on a roof, those on the surface of a hot structure were loosely attached, to expand and contract freely with temperature change.

Such structures were complex, and the shingles posed difficulties of their own. Columbium and molybdenum oxidize readily when hot, and required coatings to resist this. The Dyna-Soar had been designed to use such thermal protection, and Faget declared that “the least little scratch in the coating, the shingle would be destroyed during re-entry.” In turn, lost shingles could bring the loss of a vehicle.

NASA and Lockheed now were developing a new surface material: an insulation made of interlaced fibers of silica that could be applied to the outside of a vehicle. These could withstand temperatures of 2500 degrees Fahrenheit, making them suitable for all but the hottest areas on a reentering shuttle. The outer surface would radiate away the heat, in the fashion of the shingles. The thickness of the silica then would prevent most of the heat from reaching the vehicle’s skin. This material would not oxidize. It also was light, weighing as little as 15 pounds per cubic foot, or one-fourth the density of water.

This material would form the well-known “tiles” of the Shuttle program, being attached to the skin in the form of numerous small shapes somewhat resembling bricks. In 1969, their immediate prospect lay in simplifying the design of hot structures. These might now dispense with their shingles; engineers instead would use titanium to craft an aircraft structure, with skin covering an internal framework, then provide thermal protection by covering the skin with the tiles. [Author interview, Max Faget, Houston, March 4, 1997; proceedings, NASA Space Shuttle Symposium, October 16-17, 1969, pp. 581-591; Report MDC E0056 (McDonnell Douglas), pp. 10-11; Jenkins, Space Shuttle, p. 64.]

The design studies of 1969 raised another tantalizing prospect: that these tiles might offer enough heat resistance to build the basic structure of aluminum rather than titanium. Titanium was hard to work with; few machine shops had the necessary expertise. Moreover, its principal uses in aerospace had occurred within classified programs such as the SR-71, which meant that much of the pertinent shop-floor experience itself was classified. This metal could withstand higher temperatures than aluminum. Yet, if tiles could protect aluminum, the use of that metal would open the shuttle to the entire aerospace industry. In Silveira’s words, building aluminum airplanes was something that “the industry knew how to do. The industry had, on the floor, standards—things like, ‘What are the proper cutting speeds?’ They knew how to rivet or machine aluminum.” [Heppenheimer, Turbulent Skies, p. 209; Joe Guilmartin and John Mauer interview, Milton Silveira, Washington, November 14, 1984, p. 16.]

Hot structures, built of titanium, would continue to represent an important approach in shuttle design. As early as 1969, however, Lockheed took the initiative in designing a shuttle orbiter built of aluminum and protected with tiles. General Dynamics added its own concept, featuring aluminum protected by shingled hot structures that could keep internal temperatures below 200 °F.

At the end of 1969, the contractors’ orbiter concepts were as follows, with the boosters being similar [reports MDC E0056 (McDonnell Douglas); GDC-DCB69-046 (General Dynamics); SD 69-573-1 (North American Rockwell); LMSC-A959837 (Lockheed); Jenkins, Space Shuttle, pp. 63-71]:

| . | Configuration | Main structure | Thermal protection |

| . | |||

| North American Rockwell | Faget-type, straight wing | Titanium | Tiles |

| General Dynamics | Deployable straight wing | Aluminum | Hot structure |

| Lockheed | Delta lifting body | Aluminum | Tiles |

| McDonnell Douglas | Faget-type, straight wing | Titanium | Tiles |

These represented variants of Faget’s two-stage concept, which showed that shuttle design had come a long way during that year. Twelve months earlier, the candidate configurations included expendable boosters as well as partially- and fully-reusable concepts. The range of alternatives included the Titan III-M with an enlarged Dyna-Soar, the Star Clipper, and the Triamese. These were as mutually dissimilar as a fighter, a bomber, and a commercial airliner.

People still debated such issues as delta wings vs. straight, aluminum vs. titanium, and hot structures vs. tiles. By year’s end, however, everyone agreed that the shuttle would look much like Faget’s. This meant that the most basic issues of configuration had been settled, allowing engineers to advance to deeper levels of detail. The studies of 1970 would pursue such levels, and would lay important groundwork for the eventual evolution of complete engineering designs, explicit in all particulars.

The work of 1969 had given the space station more support than the Shuttle. The studies of that year initially had allocated $5.8 million for the station and only $1.2 million for the Shuttle; the additional funds granted for the latter at midyear, totalling less than $0.7 million, did little to redress this imbalance. In 1970, however, NASA would bring the shuttle to the forefront. In this year, the centerpiece of effort would involve two $8-million contracts for further work on the shuttle. There would be no significant amount of new funding for the station. These internal NASA decisions would point toward abandonment of the station, at least for a number of years, and elevation of the Shuttle into the sole focus for NASA’s future. [Logsdon, Apollo, p. III-26; Aviation Week, February 10, 1969, p. 17; Akridge, Space Shuttle, p. 71.]

Station Fades; Shuttle Advances

In preparation for the work of 1970, NASA and its contractors established a new set of institutional arrangements. Following a proposal of Dale Myers, the agency gave responsibility for managing the upcoming study contracts to NASA-Marshall and to the MSC. Each center would hold a complete contract, covering both the booster and orbiter. Marshall, however, would provide technical direction for the booster portion of both contracts, while MSC would give similar direction for the orbiter portions. This continued the arrangements of Apollo, which had assigned responsibility for the Saturn V to Marshall and for the Apollo moonship to MSC. [Low, Personal Notes No. 5, January 17, 1970, p. 4; Aviation Week, February 16, 1970, p. 14.]

Within the industry, competing companies made their own arrangements. There would be only two principal new study contracts, but there were many more than two firms eager for the business, and several of them proceeded to form teams. This reflected the Shuttle’s two-stage design, for the complete shuttle was likely to be too large a project for a single contractor to handle. Accordingly, Lockheed teamed up with Boeing, with the two companies proposing respectively to handle the orbiter and booster. North American Rockwell joined with General Dynamics, while McDonnell Douglas associated with Martin Marietta. [Aviation Week: January 19, 1970, pp. 17-18; February 9, 1970, p. 27.]

Another and highly important set of decisions extended the scope of Air Force-NASA cooperation. The two agencies had collaborated on a joint study of shuttle requirements as part of the work of the STG; this had led to the issuance of a three volume report in June 1969, classified Secret. That collaboration, however, had merely served the immediate needs of the STG and its supporting studies. Now, in February 1970, Paine and Seamans agreed to set up a permanent coordinating committee, with members to be drawn in equal numbers from each agency. As in the 1969 joint study, there again would be two co-chairmen: Dale Myers and Grant Hansen. Hansen had co-chaired the earlier study, while Myers would replace Mueller, on behalf of NASA. [Akridge, Space Shuttle, p. 70; NMI 1052.130, February 17, 1970. Reprinted in NASA SP-4407, Vol. II, pp. 367-368; see also p. 369.]

On the matter of crossrange, at least for the moment, they agreed to disagree. Neither agency would seek to impose its will on the other. Rather, each main study contract would conduct two design exercises in parallel: one for an orbiter with crossrange of 200 nautical miles, the second with capability of 1,500 nautical miles. The first was well within the reach of Faget’s straight-wing concepts; the second called for more than the Air Force would need. Like a baseball player who swings two bats during warmup and then finds that his single bat feels lighter, the exercise of designing for 1500 nautical miles would stretch the minds of engineers and make it easier for them to achieve the 1100 nautical miles that represented the real requirement.

From the outset, however, Paine and Seamans could agree on an important point which Paine described as “a payload volume of 15 feet diameter by 60 feet long.” Previous studies had considered payload bays not only of this size but of 22 feet diameter by 30 feet long. The new requirement reflected the needs of both agencies. [Letter, Paine to Seamans, January 12, 1970; Reports NAS 9-10960 (NASA), p. 2; LMSC-A959837 (Lockheed), p. 2; Low, Memo for Record, January 28, 1970. Reprinted in NASA SP-4407, Vol. II, pp. 366-367.]

The Air Force needed length, for its reconnaissance satellites amounted to orbiting telescopes, and these had to be long to yield the sharpest images. Moreover, such satellites were growing markedly in length. The Corona spacecraft of the 1960s, each with an attached Agena upper stage, had started at 19 feet and quickly grew to 26. The CIA was now readying a new class of satellites that would win the name of Big Bird. With dimensions of 40 by 10 feet, it represented a backup to MOL, whose length and width had been virtually the same. The next generation of satellites, called Kennan, would keep the 10-foot diameter but would grow in length to 64 feet.

Big Bird was in an advanced state of development in 1970; the first of them flew to orbit atop a Titan III-D in June 1971. Their photos gave a resolution of two feet. Kennan was still in initial studies, for it would introduce long-duration operations and the use of charge-coupled devices rather than film. Though it would not fly until December 1976, its images would show resolution as sharp as six inches.

In 1970, the size of Kennan had not been fixed; indeed, very little about this project had been fixed. It was clear to Air Force planners, however, that they would face an increasing need to launch long satellites. Accordingly, they declared that they would need a length of 60 feet for the shuttle’s payload bay.

While NASA did not need so much length, its officials wanted a 15-foot diameter to accommodate modules for a space station. This reflected a new approach to the design of such stations. The studies of the 1960s, including those that Paine had initiated in 1969, had envisioned a space station as a single unit that would fly atop a Saturn I-B or Saturn V. As the prospects for Saturns faded while those of the Shuttle seemed to advance, it appeared prudent to envision a class of stations that could be assembled in space as an array of cylindrical modules, one module per shuttle flight. A shuttle bay with this diameter would accommodate modules 14 feet across, intermediate between the 10 feet of MOL and the 22 feet of Skylab. [Richelson, Secret Eyes, pp. 48, 90, 105-106, 124-130, 361-362; Pace, Engineering, pp. 110-116.]

In addition, a 15-by-60 foot bay would serve the needs of both agencies by providing room for the space tug and its payloads. Many spacecraft would fly to high orbit, including geosynchronous orbit, and the payload bay had to address such expectations as that future communications satellites would also grow larger. Thus, when Dale Myers asked Grant Hansen to weigh the merits of a reduction to 12 x 40 feet, Hansen replied:

The length of the payload bay is the more critical dimension affecting DOD mission needs. If the payload bay length is reduced to 40 feet, then 71 of the 149 payloads forecasted for the 1981 to 1990 time period in Option C and 129 of the 232 payloads forecasted in Option B of the mission model will require launch vehicles of the Titan III family….

The 15 foot diameter by 60 foot length payload bay size previously stated as the DOD requirement is based upon payloads presently in the inventory, on the potential use of a reusable upper stage to accomplish our high energy missions, and on a capability to provide limited payload growth. This requirement is still considered valid.

In summary, should you elect to develop the shuttle with a 12 ft x 40 ft payload compartment, it will preclude our full use of the potential capability and operational flexibility offered by the shuttle…. Also, if a portion of the present expendable launch vehicle stable must be retained to satisfy some mission requirements, then the potential economic attractiveness and the utility of the shuttle to the DoD is severely diminished. [Letter, Hansen to Myers, June 21, 1971.]

On February 20, NASA officials issued the formal Request for Proposals (RFP) that would lead to awards of the Shuttle study contracts of 1970. In addition to studies of the complete two-stage vehicle, a separate RFP solicited proposals for similarly detailed studies of a main engine. Competing companies had 30 days to respond; the submitted proposals would then go before a Source Evaluation Board that would pick the winners. This board included members from the Air Force. On May 12, it chose the teams headed by McDonnell Douglas and by North American Rockwell and accepted their bids. These companies now were to proceed with 11-month studies that would carry their shuttle designs to new levels of detail, with each study contract being funded at $8 million.

A year earlier, those same companies had won similar $2.9 million contracts for studies of the space station. This reflected their strength, for they were the only firms to have designed and built both piloted spacecraft and large hydrogen-fueled rocket stages for Apollo. McDonnell had built the Mercury and Gemini spacecraft; Douglas’ credits included the S-IVB stage, MOL, and the upcoming Skylab. North American’s record included the Apollo spacecraft and the S-II, the second stage of the Saturn V. Other companies had gained strong achievements: General Dynamics’s Atlas, Lockheed’s Agena stages used with Corona, Martin Marietta’s Titan family, Grumman’s Apollo lunar module. In their experience, however, McDonnell Douglas and North American Rockwell were in a class by themselves. [Aviation Week: September 22, 1969, p. 100; February 16, 1970, p. 14; February 23, 1970, p. 16; May 21, 1970, p. 18; letter, Paine to Seamans, January 12, 1970; letter, Paine to Teague, May 28, 1970.]

They had initiated their current space station studies in September 1969. By the following July, these companies had carried their designs to a good level of detail. Their stations would take shape as a cylinder with diameter of 33 feet, suitable for launch by Saturn V, surmounted by an enormous solar array. Jack Heberlig, a space station manager at MSC, described the internal layout as “basically four decks with a cellar and an attic.” The cellar and attic would house spacecraft equipment, including storage tanks as well as noisy fans and blowers, with acoustic insulation to keep their noise from disturbing the crew. The four decks would provide room for living and working.

Space station concept of 1970, intended for launch with the Saturn V. (North American Rockwell)